Distributed generation technologies, like fuel cells, have demonstrated a track record of providing practical solutions to issues facing the grid, and no other technology can offer both the resiliency and efficiency of fuel cells, while still achieving significant emission reductions.

David Carpenter for | The Fuel Cell and Hydrogen Energy Association

America’s electricity grid is among the most reliable in the world. Every day, utilities provide electricity to our homes, businesses, and industrial facilities safely and reliably.

While few would argue that their track record has been impressive, improvements are always welcomed, particularly in the face of more frequent extreme weather, and a persistent threat of terrorist activities by physical or cyber-attack.

The Northeast has been particularly prone to service disruptions, where prolonged outages have caused significant personal and economic damage. By one account, the average downtime is 214 minutes per end-user annually. In some of these incidents, outages were caused by an aging transmission system infrastructure that failed during severe weather events, exposing the lack of resiliency of the Northeast power grid.

The Fuel Cell & Hydrogen Energy Association (FCHEA) recently released a white paper, Enhancing the Role of Fuel Cells for Northeast Grid Resiliency, examining the role fuel cells play in hardening the Northeast grid, as well as policy efforts to deploy fuel cell technologies.

Traditionally, businesses or large energy consumers utilize diesel back-up generators, to avoid costly outages. However, fuel cell technology is beginning to displace these generators as a way to save money and improve reliability.

Fuel cells generate electricity through an electrochemical reaction, not combustion, so there are no harmful emissions. With few moving parts, fuel cells are also efficient and quiet. And when utilizing natural gas lines from underground pipes, they are far less likely to be damaged by weather events.

From high efficiency and reliability, to fuel flexibility and low emissions, fuel cells provide distinct advantages over incumbent electrical generation technologies, and help answer the question of how to sustain the northeastern grid during and after a severe storm.

During Hurricane Irene, power outages left residents and businesses without power and disabled telecommunication towers for hours. However, Sprint’s fleet of ReliOn fuel cells performed flawlessly, providing emergency power to the towers for a cumulative 725 hours.

Likewise, during Superstorm Sandy, Doosan fuel cell systems in New York and Connecticut remained in operation, running independent of the grid and providing heat and electricity throughout the crisis.

Fuel cells at Price Choppers in Colonie, New York, and Middletown, Connecticut, operated independent of the grid for five and six days, allowing the supermarkets to keep food available, the lights on, registers open, and the hot water system functioning. At Stop & Shop in Torrington, Connecticut, the fuel cell system provided the grocery store with power, heating and cooling while the grid power was intermittent.

At Delmarva Power in New Castle, Delaware, Bloom Energy fuel cells continued to operate without disruption, feeding power to the grid while Superstorm Sandy passed directly overhead. Delmarva provided continuous power to more than 503,000 customers throughout Delaware and along the eastern shore of Maryland while other many parts of the electric grid remained offline.

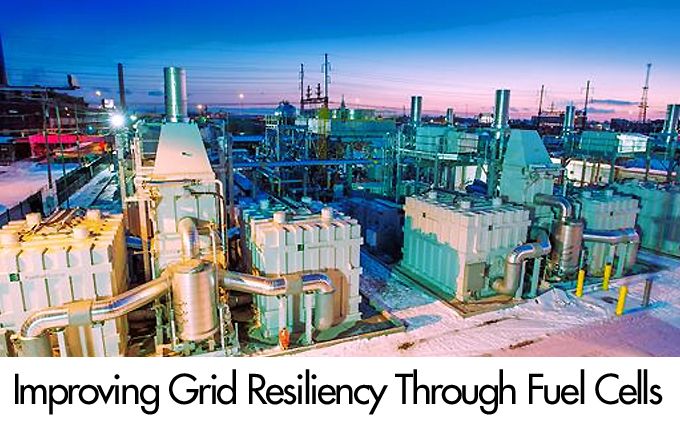

Other utilities are also adding fuel cells to their power generation arsenal to enhance grid resiliency. Dominion installed 14.9 MW of Danbury-based FuelCell Energy fuel cells in Bridgeport, generating enough power for 20,000 homes. The United Illuminating Company, also in association with FuelCell Energy, installed two 2.8 MW fuel cell power parks in Connecticut, one in Bridgeport and another in New Haven. Fuel cell parks solve power generation challenges as their combination of near-zero pollutants, quiet operating nature, and modest land-use needs facilitate their setting in urban locations.

Some states have taken a lead in encouraging resiliency through fuel cells. Connecticut, through the state’s Department of Energy & Environmental Protection (DEEP) Microgrid Pilot Program awarded funding to two fuel cell microgrid projects in 2013. Through this program, the University of Connecticut Depot Campus received installed a 400 kW fuel cell, and in 2014, the University of Bridgeport finished a microgrid project that includes a 1.4 MW fuel cell to keep critical facilities powered when the grid goes down.

In New Jersey, the Energy Resilience Bank (ERB) provides funding for facilities to invest in fuel cells.

Other Northeast state governments are also supporting fuel cells, as documented the 2014 State Policy Activity Wrap Up Fuel Cells & Hydrogen. The report aggregates state-level policies and funding opportunities that support the development and deployment of fuel cell and hydrogen technologies.

We have witnessed how vulnerable the Northeast power gird is, and without preparation, the next severe weather event could prove disastrous and very costly.

Distributed generation technologies, like fuel cells, have demonstrated a track record of providing practical solutions to issues facing the grid, and no other technology can offer both the resiliency and efficiency of fuel cells, while still achieving significant emission reductions.

It will take time to strengthen and improve the Northeast grid, but with policies that promote the adoption of fuel cells, the Northeast can reverse the trend of spotty grid resiliency and build a true 21st century electric infrastructure.

Title Image - Dominion Bridgeport Fuel Cell – Bridgeport, Connecticut. Source: Dominion.

ABOUT THE FUEL CELL AND HYDROGEN ENERGY ASSOCIATION

The Fuel Cell and Hydrogen Energy Association is the trade association dedicated to the commercialization of fuel cells and hydrogen energy technologies, representing the full global supply chain, including materials, components and systems manufacturers, hydrogen producers and fuel distributors, government laboratories and agencies, trade associations, utilities, and other end users.

The content & opinions in this article are the author’s and do not necessarily represent the views of AltEnergyMag

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product