This case study is based on a real project in South West France. Results have been validated by an independent third party.

Improving Solar Tracker Performance With SMARTracking™

Contributed by | Exosun

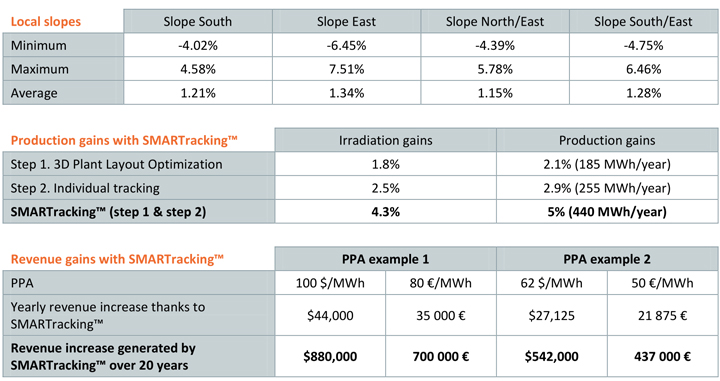

Improving solar tracker efficiency and cost effectiveness is a battle Exosun is strongly involved in. As a result, Exosun has patented SMARTracking™, a unique process allowing the Exotrack® HZ to produce up to 5% more energy than other single-axis solar trackers installed on utility-scale solar plants.

In this white paper, we will describe the SMARTracking™ process and then focus on a case study of a 6.7 MWp solar plant in France. We will answer the following question: How can energy output of solar trackers be even more optimized?

Definition of SMARTracking™

SMARTracking™ is based on a two-step process: “3D plant layout optimization” and “individual tracking implementation”.

STEP 1 - 3D plant layout optimization

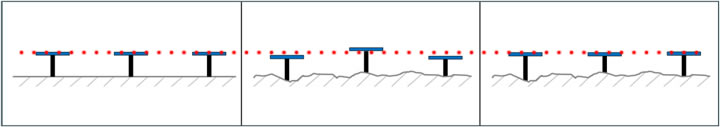

Improving the energy output of your solar plant starts at the design study phase. By performing a 3D optimization, Exosun’s design team offsets land irregularities, thereby reducing mutual shading between tables and maximizing energy yield. And since no land is flat, the 3D plant layout optimization systematically improves energy production. This step is also the best way to reduce grading needs.

Image 1. Simplified example of piles optimization and surface smoothing (East-West section)

STEP 2 - Individual tracking implementation

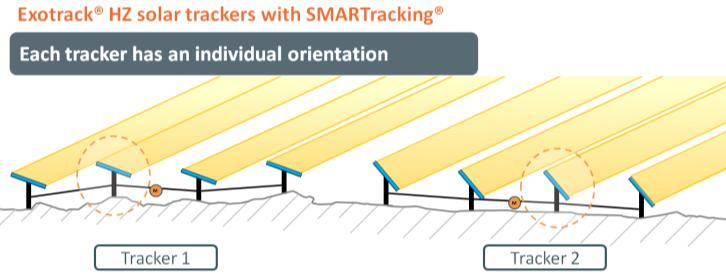

The energy output is increased by implementing a tracking program which is entirely customized to the real on- site position of each solar tracker. With a better tracking strategy, we improve the yield, whatever the site conditions are.

Each solar tracker will have a customized daily movement, independently from the other trackers on the plant. In other words, each solar tracker will have the best suited position at each moment of the day, thus improving even more the energy output.

Image 2. Example of the individual kinematics of two trackers. (the orange circles indicate the critical table that defines the tracking angle of the tracker)

This case study is based on a real project in South West France. Results have been validated by an independent third party.

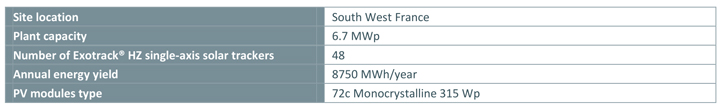

Project overview and data

The following table summarizes the project data:

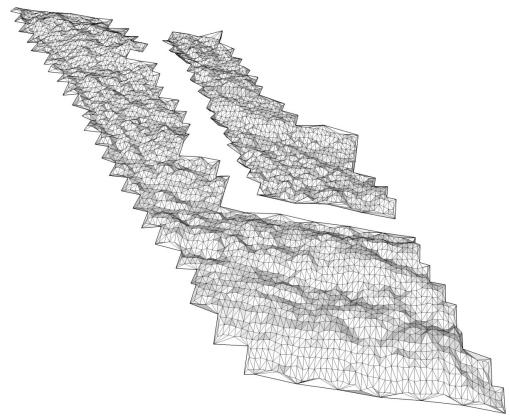

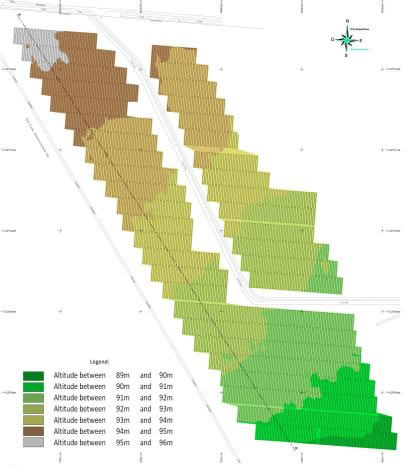

Site topography and layout

Image 3. Site terrain topography (left) and site layout plan (right)

Over 20 years and with a 100 $/MWh PPA, SMARTracking™ allows to generate a revenue increase of $880,000 (700 000 €) for this specific 6.7 MWp plant in France. This simplified evaluation does not take into account the time and money savings linked to grading needs reduction and tables mounting issues prevention.

About Exosun

Expert in solar tracker technology for utility-scale plants, Exosun offers a new approach to the market.

With its high value of innovation, Exosun designs breakthrough products and processes. Beyond the simple supply of trackers, Exosun offers a complete solar tracking systems and associated engineering services adapted to each project and that perfectly answer to the needs of its clients and partners.

With its high value of innovation, Exosun designs breakthrough products and processes. Beyond the simple supply of trackers, Exosun offers a complete solar tracking systems and associated engineering services adapted to each project and that perfectly answer to the needs of its clients and partners.

In parallel, Exosun is highly committed to R&D and has dedicated teams that work exclusively on developing new solar technologies that answer to the growing worldwide energy needs.

The content & opinions in this article are the author’s and do not necessarily represent the views of AltEnergyMag

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product