Foundations are critical to the success of a wind turbine project, and since foundation types are as varied as the earth conditions and types of structures being supported, we examine below some of the considerations involved in foundation selection such as siting, cost, and geotechnology.

In Support of Wind Energy: The Foundations that Underlie Wind Projects

Michael Byle | Tetra Tech

Introduction

Wind turbines are getting larger and more powerful. Accordingly, these high capacity turbines apply larger loads to their foundations, the structures that transfer weight from the turbines to the earth.

In general, foundations are usually simple concrete blocks called footings that are placed under building walls and columns, or in the case of wind turbines, beneath the tower. The performance of this type of foundation depends on the strength and compressibility of the soil or rock that may be present under the footing. The soil or rock conditions affect the size and depth of the footing. Where soft soils are present, it may be necessary to use pilings to carry the load down to a deeper layer that has greater strength.

In general, foundations are usually simple concrete blocks called footings that are placed under building walls and columns, or in the case of wind turbines, beneath the tower. The performance of this type of foundation depends on the strength and compressibility of the soil or rock that may be present under the footing. The soil or rock conditions affect the size and depth of the footing. Where soft soils are present, it may be necessary to use pilings to carry the load down to a deeper layer that has greater strength.

Wind turbines are most often mounted on towers that can be 80 meters (260 feet) or more in height. The blades can exceed 45 meters (150 feet) in length. The wind blows against the blades causing them to rotate to generate power, but it also blows against the nacelle (generator housing) and the tower. This causes the tower to tend to tip and the foundation must resist this and be stiff enough to keep the tower from rocking when acted upon by wind or earthquake. Foundation costs can vary by 100% or more where poor soil conditions are encountered and selecting a suitable foundation in advance of construction can shave months off the time for construction.

Foundations, then, are critical to the success of a wind turbine project, and since fundation types are as varied as the earth conditions and types of structures being supported, we examine below some of the considerations involved in foundation selection such as siting, cost, and geotechnology.

Siting and Constructability Factors

The location of the site and the foundations on the site may be restricted by environmental and cultural resource issues. Access difficulties affect both investigation and construction. Soils and geologic conditions may also vary across a project site. It is possible to have deep soft soils and shallow bedrock within the same project site. When these conditions are discovered early, the impact can be determined and planned for.

The design of the foundations may affect the speed (and cost) with which they can be constructed. The type size and arrangement of reinforcing can affect the time required to place it. It can also affect the rate at which concrete can be placed. Load testing of pilings and other elements of deep foundations can take time that must also be accounted for in the schedule.

Cost Factors

Cost for foundations may be broken down into design cost, construction cost, operations and maintenance (O&M) cost. Design cost is frequently the smallest foundation-related cost and yet has the most significant impact on the other costs. In variable soil and rock conditions, the failure to do sufficient geotechnical investigation can result in an inappropriate design that may not be discovered until construction, when the cost to make a change is high. While an off-the-shelf design may be available for relatively low cost, it will not necessarily be an economical or appropriate foundation for a given site. Since multiple foundations are typically constructed from a single design, optimization can pay dividends.

Construction cost is the money it takes to actually build what is on the plans. The price bid is only as good as the documents. Misinterpretations or simplifying assumptions can pave the way for change orders and disputes that can elevate the construction cost significantly above the original bid. A well-conceived design, based on good geotechnical information and put forth in a complete set of detailed drawings and specifications, is essential to getting a bid that will be reflective of the final cost. Some variation in conditions is normal, but thorough investigation and testing can reduce soil related changes.

Operations and Maintenance cost is seldom a big issue for most foundation systems. While some proprietary and anchored systems require periodic monitoring and tensioning that must be considered in evaluating their life cycle cost, most conventional foundation systems require almost to no maintenance.

Geotechnology

Soil and rock conditions play an important role in the selection and design of foundations. The evaluation of these conditions and the evaluation and selection of foundation types is done by a geotechnical engineer. An initial evaluation can be made by reviewing published data, including geology maps, soil survey maps, highway department records, conditions/experiences from previous projects in the area and other reports, studies, and maps. It is a generally a good idea to have a “desktop” geotechnical evaluation done by a geotechnical engineer during the early part of the project planning as part of a critical issues analysis. It is important when doing such studies to investigate geologic hazards such as sinkholes, swelling soils, collapsing soils, underground mining, surface mining, surface spoils from mining, landslides, earthquake issues, volcanic activity, etc. , since these can have a significant effect on the foundations.

Investigations: To determine the conditions in sufficient detail to design the foundations, the earth must be sampled to identify its type and properties. This is commonly done by drilling holes into the ground and collecting samples by either driving or pressing a tube into the soil. Where there is rock, it is usually sampled using a diamond coring tool. The samples are then tested in a laboratory to determine the strength, compressibility, and other properties needed for design.

Other methods of investigation can be completed including special devices that are pressed into the ground to measure soil strength and other properties. Geophysical testing including ground penetrating radar, electrical resistivity, seismic testing, etc. provide additional data to supplement borings and can provide detail of variability.

Geotechnical Design

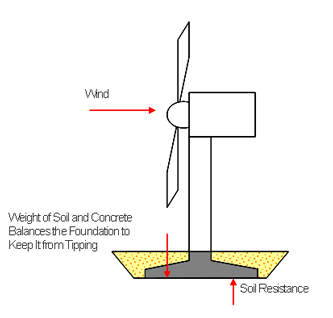

The geotechnical engineer will use parameters from field and laboratory testing together with loads from the turbine and tower to evaluate the support conditions and select a foundation type. The first step is typically to assess the suitability for support by a spread footing or mat, since that is a common and relatively inexpensive foundation type. The typical function of a spread footing is shown on Figure 1.

Fig 1 Spread Footing. This figure demonstrated how a spread footing works to resist wind load. Concrete mass and soil bearing under the toe resist overturning forces.

Where soils are soft, loose or otherwise unsuitable, alternate foundation approaches are considered. Sometimes soil improvement methods can be used to improve poor soils to make them suitable for spread footings. For other conditions, deep foundations such as driven or drilled piling may be necessary. Deep foundations may include single piers (caissons), groups of driven piles, or groups of drilled piles. Piles may be made of steel or concrete depending on cost and installation factors.

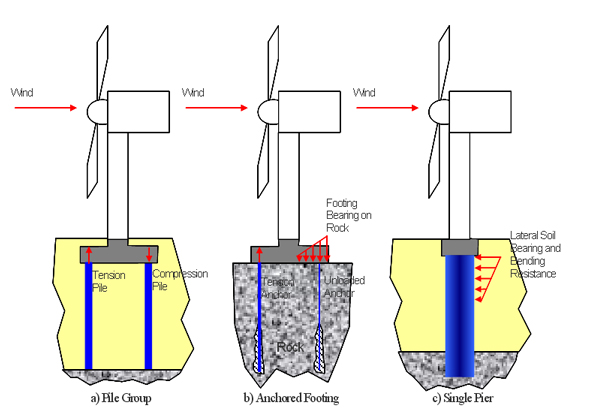

Deep foundations function differently than spread footings. Spread footings rely on soil bearing and the weight of the foundation itself and the soil backfill on top of the foundation to resist tilting under wind loads. Single piers (see Figure 2c) use the bending strength of the pier to resist tilting. For groups of piles (see Figure 2a), the tilting resistance comes from tension in the piles on one side of the foundation while piles on the other are loaded in compression.

Another option is the anchored foundation. This consists of a spread footing that has anchors extending through it into bedrock (see Figure 2b). This foundation eliminates the need for soil cover and takes advantage of high strength rock at the surface.

Several different foundation types may be technically feasible and appropriate. If this is the case, the selection is based on a multidisciplinary evaluation of all of the factors including cost, time of construction, availability of equipment and materials in the project area. Alternative deep foundations are illustrated in Figure 2.

Structural Design

Structural design of foundations will include design of the footing or pile cap and may include structural evaluation of the piles, anchors or drilled piers. Most all footings and pile caps are constructed of concrete. In order to prevent cracking of the concrete and to add strength, steel bars are included in the concrete. If concrete materials are unavailable and have to be shipped in from a great distance, it might be economical to add steel to reduce the concrete quantities or vice versa where steel is costly.

Code Compliance

Most design and building codes were not written with wind turbines in mind since the codes are primarily directed toward buildings. This leads to gray areas in structural design of foundations. When a wind turbine foundation is under extreme wind loading, the foundation will not bear on the soil or rock over the entire foundation. Typically foundations are designed to bear on 50% of the total footing area during extreme loading events. The American Concrete Institute (ACI) building code does not address this directly, leading to confusion and different interpretations. Taking a conservative interpretation would be an easy solution, but this can add considerable cost to the foundations and can nearly double the amount of steel reinforcing needed in a foundation. Tetra Tech is presently engaged with the ACI to revise the code to clarify this point and update the concrete code. There may also be conflicts between the turbine and tower design methods used by wind turbine manufacturers and those required by the codes.

Fig 2 Deep Foundations. This figure illustrates how three different deep foundation systems resist wind loads on wind turbine generators.

Integrating Permitting, Design, and Construction with Foundation Design

There are a number of approaches to project organization and management that drive the way the foundations systems are conceived, designed, and constructed. A common approach is for the owner/developer to contract for different services at different times from different companies as the planning and design proceed, and then to bid out the resulting design to a general contractor. This results in having separate consultants for environmental science and permitting, geotechnical engineering, electrical engineering, civil engineering, structural engineering, and possibly others. Some of these consultants must work sequentially; waiting for the work of others to be completed before they begin, and others must work concurrently with others, requiring close coordination.

With such large teams, communications can break down and schedule may be sacrificed to allow for sequential tasks and multiple review cycles among the various parties. Design changes are frequent where separate consultants’ work depends on each other’s work product. In many applications this multi-consultant-contractor approach can achieve a reasonable outcome; however, for fast track projects, this is often not the case.

A better approach for fast-track projects is consolidating the various services under a single full service company. In this way, there is only one entity accountable. This eliminates duplication of effort, since a full service company can provide permitting, design, and construction. Combining the permitting, design, and construction in a single full-service contract accelerates schedule, improves design, improves method and materials efficiencies, increases environmental compliance, and reduces total cost.

Conclusions

Foundations are an essential element of a wind energy project. The type and cost for foundations can vary considerably depending on site geology and history. A variety of deep and shallow foundation systems are available and can be optimized to specific project requirements. Investigating the geotechnical issues early in a project can save time and cost later in project development. Integration of the investigation, design, and construction can produce economical and efficient foundation designs that reduce the total project cost and shorten the time needed from inception to completion for the project schedule.

The content & opinions in this article are the author’s and do not necessarily represent the views of AltEnergyMag

Comments (0)

This post does not have any comments. Be the first to leave a comment below.