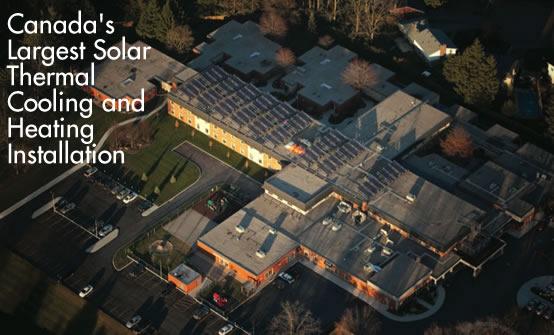

The Solar Thermal System at Oxford Gardens

Contributed by | Enerworks Inc.

Oxford Gardens is a recently renovated retirement home in Woodstock, Ontario. This 9,900 square meter building has 112 residents and 101 individual suites. A 90 ton chiller is currently used to air condition the facility and 3,000 litres of hot water are used on a daily basis. The solar cooling and thermal heating project presented by Enerworks Inc. and their German-Canadian consortium enables the management of the retirement home to achieve significant energy savings for their hot water heating, pool heating, space heating, as well as substantial savings in air conditioning through the absorption chiller.

The independent living retirement facility has created a resort style environment for the residents. The home features a swimming pool, theatre, sun room and large gardening and outdoor area.

The innovative project is proposed by a consortium of German and Canadian companies s-power, NARVA and Enerworks Inc. including local partners, such as Trigon Construction Management, Oxford Plumbing, and Zolarayz.

The up-to-date largest Canadian solar-cooling project has been awarded by the „dena Solar Roofs Program for Foreign Market Development 2009/10“. The program is coordinated by the Deutsche Energie-Agentur GmbH (dena) - the German Energy Agency - and is carried out in the framework of the „Renewable Energies Export Initiative“ of the German Federal Ministry of Economics and Technology (BMWi). It offers comprehensive support for German solar energy companies wishing to enter promising export markets.

What is Solar Thermal Power:

Solar thermal installations consist of a solar thermal collector on the roof, a control unit with a pump and a potable water storage tank. The collector absorbs the light from the sun and converts it into heat. This heat is transferred to a liquid which circulates through the collector and down into the solar storage tank.

DESCRIPTION OF THE INSTALLATION

The installation of the solar panels is currently the largest solar thermal cooling and heating project in Canada. It involves 162 solar thermal collectors being assembled onto the roof of the retirement home. Each of these collectors, made by the German company S-Power, includes 20 evacuated tubes produced by NARVA, a German company as well. The collectors are installed over 9 rows with 18 collectors per row. This combination includes 3,240 tubes. The S-Power evacuated tube collectors use 30-40% less space than other solar collectors making it possible for them to fit onto the roof of the facility. A propylene glycol mixture designed specifically for high temperature solar thermal applications flows through the tubes collecting the heat. Over 17,000 litres of solar-glycol is used in the system.

The collectors are mounted to aluminum racking which is attached to metal cladded laminated wood beams. These beams are attached to mounting supports which are then fastened through the roof to the main structural walls of the building. The collectors are assembled well above the snow line of the roof, to enable them to function properly all year. Piping sizes on the project ranges from ¾” at the collectors all the way up to 4” into the mechanical room. All piping is stainless steel outside with some copper inside. Over 4,000 feet of insulated piping was used to connect the system.

The Yazaki WFC-SC 30 ton (105kW) absorption chiller and storage tank are installed on the 13” thick concrete equipment pads. In addition to the concrete pads required for the equipment, additional concrete was poured, making a patio for the residents of the home.

The Yazaki Absorbtion Chiller

The Yazaki absorption chiller is connected to the existing central cooling system and will reduce the electrical consumption of the two TRANE chillers. This chiller will convert the solar hot water into chilled water.

Thermal energy will be stored in a 3,000 gallon storage tank which will be used as a ‘battery' to store energy and allow the system to operate during intermittent clouds or after the sun has gone down. The tank has been insulated with urethane foam and painted for UV protection.

The Heat Exchanger

The mechanical room houses the heat exchanger, pumps and the control system. The heat exchanger is a double wall plate on frame exchanger which weighs 1,800 lbs and is able to transfer 1.2 million BTUs per hour to the heating system. The solar domestic water uses a 500,000 BTU double wall brazed plate heat exchanger and the swimming pool uses a 500,000 BTU shell and tube heat exchanger.

Each of the heat exchangers use a pump to pull hot solar fluid from the storage tank when needed and pushes it through the heat exchanger to transfer the heat.

The Control Unit

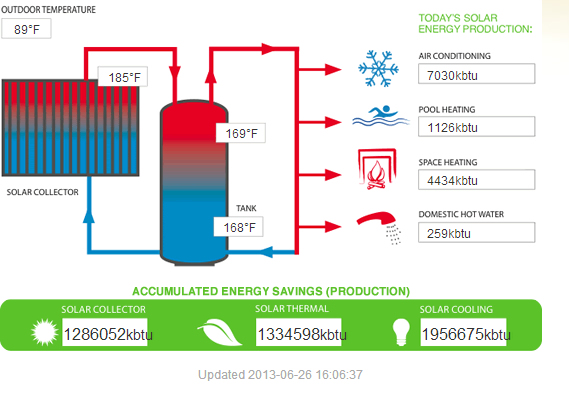

The control unit is a touch screen control provided by Enerworks Inc.. The control is very sophisticated and coordinates all functions of the system. The control measures total output of the solar system as well as the solar contribution for each load (swimming pool, domestic water, heating system and cooling system). This allows us to monitor the effectiveness of what has been collected against what is being used.

There is a back up heater (or chiller) for each load point. These were existing and will continue to operate as they always have, should the solar system not provide enough energy on a rainy day or snow storm. The integration is seamless so the residents will see no interruption of services.

Technical Data:

System Components:

- Collectors: 162 S-Power 20/2000 TPS inside

- Installed collector power: 364 kW

- Total gross surface area: 526.5 m²

- Domestic hot water stand by tank: 3000 gal.

- Solar preheating tank: 2 x 450 L

- Yazaki WFC-5C30 absorbtion chiller

ONLINE PERFORMANCE DISPLAY

Enerworks, Inc.

Committed to being a leader in the Solar Thermal Industry, Enerworks Inc., established in 2008, in Woodstock, Ontario, is an international supplier of solar thermal technology to the North American renewable energy sector.

Committed to being a leader in the Solar Thermal Industry, Enerworks Inc., established in 2008, in Woodstock, Ontario, is an international supplier of solar thermal technology to the North American renewable energy sector.

From its inception, Enerworks Inc. has been a committed leader in the solar thermal industry.

Enerworks Inc. is the exclusive distributor for the German S-Power™ evacuated tube collectors, which feature the award winning Narva™ brand evacuated tubes. These leading technologies within the renewable energy field, coupled with the development of distribution and sales agents throughout Canada and the USA, gives Enerworks Inc. the competitive edge to provide quality and efficient products to the solar thermal industry.

Designed to replace traditional fossil forms of energy, which are facing increasing costs and harmful effects to the environment, solar hot water heating systems are costeffective, require minimal service and save money.

“The largest single benefit to the industry is cost containment or cost reductions. A secondary and equally important value will be the significant reduction of CO2 emissions. We take our role in the renewable energy industry very seriously because our products will have an impact on protecting the climate for generations to come “ states Suni Ball, general manager of Enerworks Inc..

Enerworks Inc. has designed the largest commercial scale solar cooling and thermal heating system in Canada. This system has been constructed at Oxford Gardens, a Retirement Village in Woodstock, Ontario.

Committed to the renewable energy industry, partnering with companies who foresee the importance of alternative energy, providing quality products and service to customers have led Enerworks Inc. in their commitment to be a leader in solar thermal cooling and heating technologies.

The content & opinions in this article are the author’s and do not necessarily represent the views of AltEnergyMag

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product