In Support of Wind Energy: The Foundations that Underlie Wind Projects

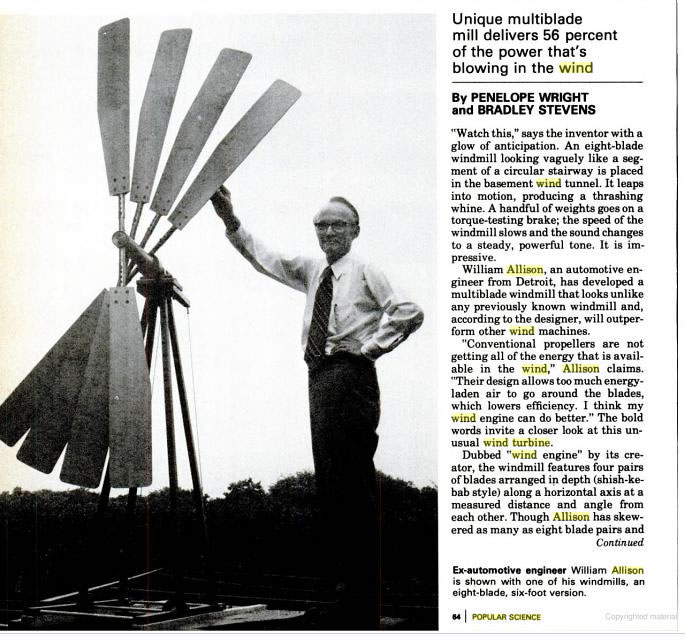

Wind Powered Engines And The Elusive 59% Efficiency

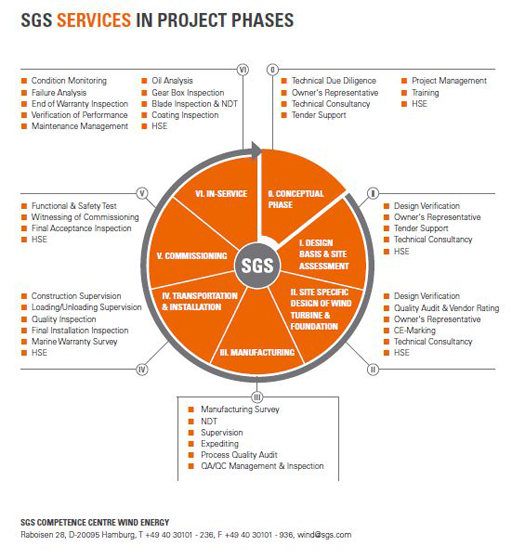

Wind energy: Why is project certification so important?

Condition Monitoring for Wind Turbines

Interview - 20% Energy from Wind by 2030 - A Reality Check

Interview - Community Winds Coming of Age

Offshore Wind

The Maine Wind Industry Initiative

WHY 2 BLADED ROTORS MAKE SENSE

Better Wind Turbine Transmission

MIT Clean Energy Entrepreneurship Prize

SMALL-SCALE WIND ENERGY

Need for Wind Energy Professionals Will Rise

SGS Conducts QHSE Management for the Belwind Bligh Bank Offshore Wind Farm in Belgium

Testing times for wind turbines

Records 31 to 45 of 50

First | Previous | Next | Last

Featured Product