Wood Pellet Mill For Sale

RICHI MZLH series wood pellet mills for sale, which are suitable for all types of wood materials (sawdust, shavings, chips, logs, pallet…). This equipment is an honorary product of Richi Machinery.

The wood pellet mill is a special equipment for producing wood pellets, usually cylindrical, with a diameter of not more than 25 mm and a length of not more than 4 times its diameter; common diameters are 6mm, 8mm, 10mm.

Richi Machinery has nearly 30 years of experience in the production of wood pellet mill equipment, and has been engaged in the renewable wood pellet mill for sale, and at the same time provides a complete set of biomass pellet production line design.

Types Of Wood Pellet Mill for sale

According to the different raw materials used by customers, wood pellet machines can be divided into wood chip pellet mill, sawdust pellet machine, wood shaving pellet machine, wood pallet pellet mill, etc.

The wood pellet mill is a model of the combination of mature pelletizing technology and mechanical manufacturing. Its special ring die structure design, wear-resistant material technology, pelletizing speed optimization and gear design can be used for heating, power generation, fuel, cat litter, etc. The application provides good quality wood pellets and is ideal for wood pellet processing.

Our wood pellet mill is suitable for the processing of any kind of wood pellets, no matter what form your raw material is, as long as it is made of wood, our wood pellet mill machine can pelletize it.

For different types of wood pellet processing needs, we provide you with one-stop wood pellet mill and wood pellet plant solutions.

Advantages Of Wood Pellet Mill machine

RICHI wood pellet mill is a high-capacity and intelligent new type of pelletizing equipment that benchmarks against the international wood pellet mill technology.

Compared with the traditional wood pellet mill, the RICHI ring die wood pellet mill has higher pelletizing efficiency, lower operating cost, convenient maintenance and adjustment, and can provide users with a large-capacity pelletizing solution.

Our wood pellet mills for sale more than 130 countries around the world, have the following advantages:

- The wood pellet mill adopts high-precision involute cylindrical helical gears for direct transmission, and the transmission efficiency is as high as 98%.

- Normalizing heat treatment after water forging of the transmission gear tooth blank improves the hardness of the tooth surface; the tooth surface is carburized, and the carburized layer is as deep as 2.4mm to enhance the wear resistance and prolong the service life of the parts; The tooth surface is processed by the silent fine grinding and edging process, which makes the operation quieter and more stable.

- The main shaft and the conjoined hollow shaft are made of alloy structural steel through water forging, rough turning, heat treatment and fine grinding. The wood pellet mill structure is reasonable and the hardness is uniform, which improves the fatigue resistance and wear resistance of the parts, and provides more safety for the operation.

- The main machine box is made of high-quality steel, with uniform thickness and compact structure; it is carefully processed by the CNC machining center, and the machining accuracy is zero error, which provides stronger support for normal operation.

- The ring die wood pellet mill machine adopts the structure of double pressing rollers, and the force is relatively uniform. The pressed pellet products have high forming rate, high density, good quality, and are easier to store. At present, the pellet fuel has a stable commercial market.

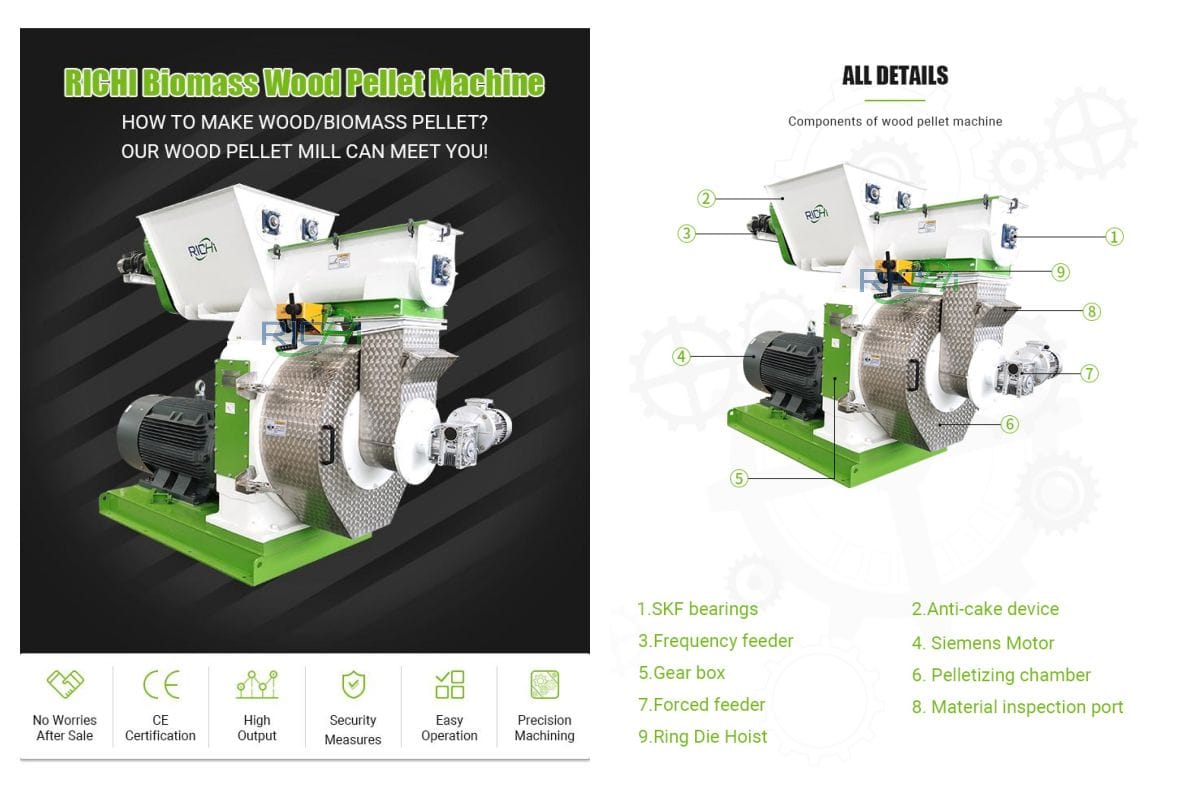

- The bearings used in the wood pellet mill use high-quality SKF bearings, and a thin oil circulation cooling and lubrication system is added, which has a longer bearing life and safer operation. The use of original spare parts is a key element in maintaining high productivity and long service life.

- The wood pellet mills ring die is made of stainless high-nickel steel, and the unique compression ratio design is reasonable, so that the product quality is better, the service life of the ring die is longer, and the production cost is greatly reduced.

- Since the inner diameter of the ring die of the commercial wood pellet mill does not exceed 500mm, the ring die can be cast as a whole; it is driven by the dynamic mode, the feeding is convenient, and a higher speed can be obtained; the pellet product has good quality and high density , can reach 1.2-1.4 t/m3, the productivity is 1.5-2 t/h, and the forming rate is not less than 95%.

According to the specific requirements of customers, we can tailor-made wood pellet mill for sale and supporting overall design. Through the optimized combination of various types of equipment, different wood pellet mill plant process requirements can be met.

Parameters Of Complete Wood Pellet Mill

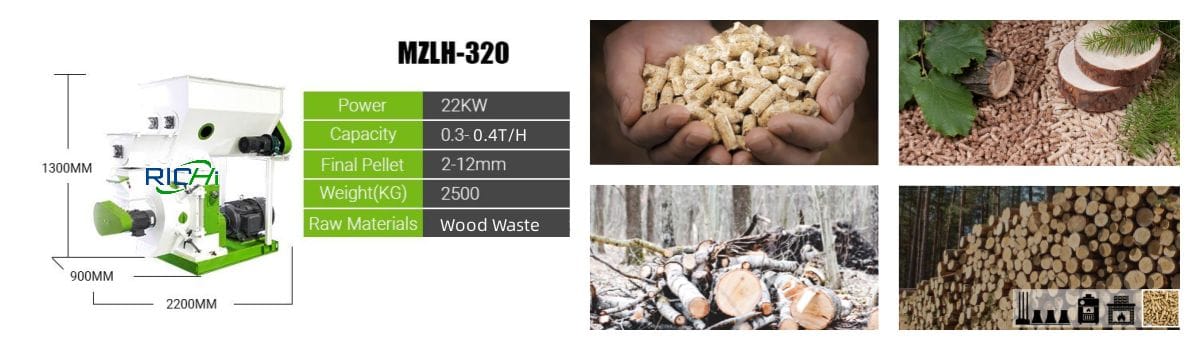

MZLH320 Wood Pellet Machine For Sale

Power: 37KW

Capacity: 300-400KG/H

Final Pellet: 6-12 mm

Weight(KG): 2500

MZLH350 Wood Pellet making machine For Sale

Power: 55KW

Capacity: 500-700KG/H

Final Pellet: 6-12 mm

Weight(KG): 3500

MZLH420 Wood Pellet Maker For Sale

Power: 90KW

Capacity: 1.0-1.2 T/H

Final Pellet: 6-12 mm

Weight(KG): 4000

MZLH520 Wood Pellet Press for sale

Power: 132KW

Capacity: 2.0-2.5 T/H

Final Pellet: 6-12 mm

Weight(KG): 4500

MZLH768 Wood Pelletizer for sale

Power: 250KW

Capacity: 2.5-4 T/H

Final Pellet: 6-12 mm

Weight(KG): 5000

MZLH858 Wood Pelletizer machine

Power: 280KW

Capacity: 3-4.5 T/H

Final Pellet: 6-12 mm

Weight(KG): 5500

Customizable Design:

We can customize the biomass wood pellet mill for sale the world according to the actual needs of customers, including voltage, electrical components, product color matching, and can also customize biomass pellet mill process, biomass pellet mill parts and different compression ratio according to different biomass raw materials, etc.

For a long time, Richi Machinery has focused on the R&D and manufacturing of wood pellet mill equipment and the wood pellet mills for sale, and provides professional wood pellet production solutions and mature supporting products to create value for customers. Richi Machinery will customize a reasonable production plan for the user, and configure and install it according to the user’s needs.

Wood Pellet Mill For Sale The World

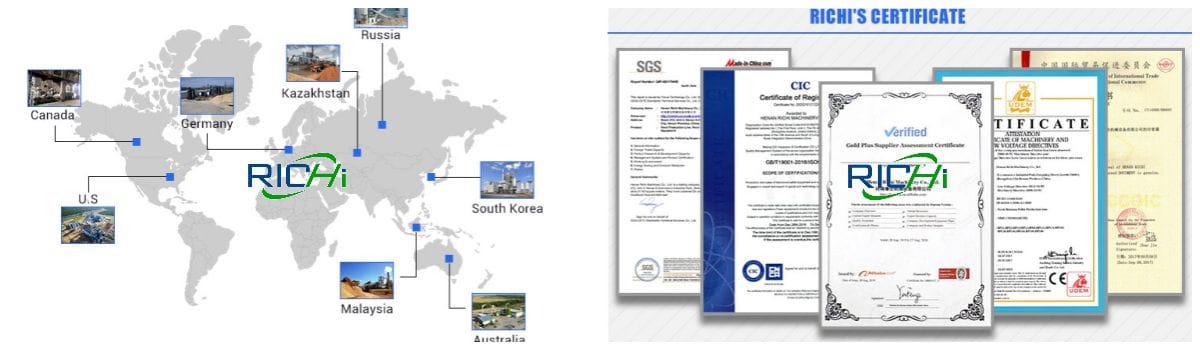

Richi Machinery is mainly engaged in R&D and manufacturing of wood pellet mill, providing technical solutions and supporting products. Have exported wood pellet mill for sale more than 120 countries and have reached strategic cooperation with thousands of customers around the world.

Completed Wood Pellet Mill Projects

- pellet mill for sale usa

- pellet mill for sale australia

- 5T/H wood pellet mill for sale Austria

- Biomass wood pellet plant in Indonesia

- 2-2.5 T/H wood pellet mill for sale Germany

- Wood pellet machine for sale Canada

- 4-5T/H sawdust wood pellet mill equipment for sale Indonesia

- 1-1.5 T/H wood pellet mill for sale Iceland

- 1-1.2T/H wood pellet mill for sale Congo

- 10T/H wood pellet mill for sale Mexico

- MZLH320 sawdust wood pelletizer for sale Indonesia

- MZLH320 sawdust wood pelletizer for sale Indonesia

- …

Wood Pellet Mill Projects Under Construction

- 10-15 T/H wood pellet mill for sale united states

- 2-2.5 t/h wood pellet mill line for sale Thailand

- MZLH350 wood pellet mill machine for sale Thailand

- MZLH420 wood sawdust pellet mill for sale Malaysia

- 2T/H wood pellet mill plant for sale Singapore

- 1.5T wood biomass pellet production line for sale Japan

- MZLH350 wood pellet making machine for sale Korea

- MZLH420 and MZLH520 wood granulator for sale Brazil

- 4-5T/h wood pellet mill for sale Argentina

- 2-3T/H wood pellet machine for sale Trinia Tobago

- 1-1.2T/H wood pellet production line for sale Angola

- MZLH520 wood pellet mill machine for sale South Africa

- …

wood pellet mill for sale Russia

- project date: 2020.09.03

- Pellet Size: 6mm

wood pellet mill for sale Canada

- project date: 2021.9.27

- Pellet Size: 8mm

wood pellet mill for sale USA

- project date: 2020.10.11

- Pellet Size: 6-8mm

wood pellet mill for sale Argentina

- project date: 2020.06.15

- Pellet Size: 8-10mm

wood pellet mill for sale France

- project date: 2023.06.11

- Pellet Size: 6-10mm

wood pellet mill for sale brazil

- project date: 2020.07.28

- Pellet Size: 8-10mm

wood pellet mill for sale Germany

- project date: 2019.05.07

- Pellet Size: 8mm

wood pellet mill for sale India

- project date: 2022.07.12

- Pellet Size: 8-10mm

We have hundreds of wood pellet mill & wood pellet plant projects (completed and under construction), no matter what kind of wood or wood form your raw material is, you are welcome to consult Richi Machinery at any time, I believe our experience can effectively help you with wood pellet production.

Wood Pellet Mill Price

No matter which country you are from, the wood pellet mill price is the same, the only difference is the shipping cost and some customized designs.

The wood pellet mill price is generally 10000-100000USD, which is the price of a single pellet mill for wood. But generally speaking, except for customers who need to replace the wood pellet machine, for most other customers, it is not enough to know the price of the biomass wood pellet mill, because to realize the processing of wood pellets, multiple wood pellet mill plant equipments are often required.

It can be understood that most customers need a complete wood pellet mill plant system, but the design of each customer’s wood pellet system is different, and the price is also different. This is related to many factors, which requires understanding the customer’s wood pellet mill plant site planning, processing raw materials and other production conditions.

Taking the processing raw material as an example, if it is dry sawdust, the customer’s granulation system will be relatively simple, because it does not require a lot of pre-treatment equipment.

If the customer’s raw material is a log with high humidity, it needs to be configured with a more complex wood pellet mill plant configuration, including wood splitter, slicer, pulverizer, wood chip dryer, etc.

In addition, wood pellet making equipment capacity is also an important factor affecting the wood pellet mill cost. Finally, it is the use of the material, whether it is for self-use or sale; the properties of the finished product such as particle size and moisture content of the output will affect the investment cost of the wood pellet processing system to a certain extent.

According to the above factors, RICHI engineers will come up with a set of detailed customized solutions that meet the needs of customers, including wood pellet mill price and selection, so it’s impossible to simply tell the wood pellet machine price without being sure of the customer’s needs.

Richi Machinery specializes in wood pellet mill for sale. If you have a demand for wood pellet mill equipment, you are welcome to consult online or WhatsApp, and Richi Machinery will customize a wood pellet mill plant configuration that is more suitable for your specific situation according to your output, raw materials, and finished pellet size.

Working Principle Of Wood Pellet Mill

Whether it is sawdust, shavings, or wood log, tree trunks, branches, or heavy wooden pallets, our wood pellet mills for sale, covers the entire process chain of processing all types of wood pellets

RICHI wood pellet machine adopts annular die and matching cylindrical pressure roller as the main working parts, which is mainly composed of feeding, stirring, transmission and lubricating systems. Because the axis of the die is usually arranged horizontally, it is often called a horizontal ring die wood pellet mill.

The raw materials are stirred and mixed by specially configured copying plates in the batching bin, quenched and tempered, and then the screw feeder feeds the materials into the electric wood pellet mill for granulation.

In the best wood pellet mill, the screed plate evenly distributes the quenched and tempered materials between the ring die and the pressing roller. The biomass wood pellet mill ring die is driven by the motor to rotate, and the two pressing rollers installed in the ring die only rotate but do not revolve under the action of the material between the die rollers and the friction between them.

Due to the rotation of the wood pellet mills ring die and the pressing roller, the material between the die and the roller is clamped and squeezed, and finally extruded continuously from the die hole in a column shape, and then cut into a certain length of pellets with a cutter.

Note: Generally speaking, the wood pellet mill does not work alone, and also needs a lot of equipment to cooperate. Therefore, a complete set of wood pellet mill plant system process mainly includes raw material drying, pulverization (dust removal), air conveying, collection, raw material mixing and stirring, screw conveying, granulation molding, cutting, cooling, packaging, storage and other processes.

Richi Machinery is not only focusing on wood pellet mill for sale, but RICHI wood pellet production line solutions have become more and more mature after nearly 30 years of operation. This type of solution includes technical assistance in the entire process of production line design, site planning, and process plan, and is tracked and responsible by the project manager, making the project progress and cost input more clear.

How To Choose Commercial Wood Pellet Mill?

How to choose biomass wood pellet mill? Choose large or small wood pellet mill? In recent years, biomass pellet investment projects have become more and more popular, and wood pellet machine is an important equipment for producing biomass pellet fuel.RICHI specializes in wood pellet mill for sale, next let us give you some advice.

Many customers have considered this: first buy a small wood pellet for small production, cheap investment, and then use it, start with a small investment, and then increase the investment after making money. In fact, it is normal to have such an idea, but when choosing wood pellet mill plant equipment, you need to see the following points:

(1) Preliminary Preparation

Make a good investment budget, inspect raw materials, workshops, electricity, and sales markets.

(2) Equipment According To Materials

Different materials have different wood pellet mill process and require different equipment. Energy consumption and output, maintenance costs, whether they can be easily repaired, whether wood pellet mill parts are wear-resistant, and whether they are easy to operate need to be considered. Find a few more wood pellet mill manufacturers to explain the situation, and they will make a plan for you free of charge.

(3) Choose A Reliable Wood Pellet Mill Manufacturer

On-site inspection, when necessary, you can bring materials to test the machine. Regular wood pellet mill manufacturers generally have after-sales training to learn how to use the wood pellet mill machine.

Facts have proved that a good operator not only has high granulation efficiency, but also knows how to maintain the electric wood pellet mill and prolong the service life of the machine.

(4) Select Large-Scale Wood Pellet Mill

Under the same production task, the large-scale wood pellet mill saves labor and facilitates management. So, find a professional wood pellet mill manufacturer who can tell you this, and specializes in wood pellet mill for sale.

For example, the scale of the wood pellet mill plant with 8 wood pellet mills can save hundreds of thousands of dollars in labor costs every year. And the large-scale pellet machine saves the floor space and saves more than half of the space. It also saves maintenance and spare parts, spare parts purchase and replacement time, labor required for replacement, etc.

Generally speaking, large-scale wood pellet mills have more advanced design, better stability and performance, large motor power and torque, wide moderation, easier production, easier scale effect, and lower production costs. The overall stability of the machine is good, and the wood pellet mill cost is naturally high.

Richi Machinery not only provides a single wood pellet mill for sale, but also a complete set of wood pellet plant equipment. With the help of RICHI’s complete wood pellet mill solutions, customers can choose within a more precise range even if they do not know the equipment, reduce energy and financial investment, and focus on controlling the project progress.

How To Build A Wood Pellet Mill Plant?

Generally speaking, the ultimate purpose of purchasing a wood pellet mill is to realize a complete wood pellet production line. This wood pellet mill plant can be simple or complex, depending on the customer’s raw materials, customer’s investment, floor space and other factors.

Richi Machinery specializes in wood pellet mill for sale. No matter what kind of raw material you are, we can provide suitable wood pellet mill equipment and process solutions.

Richi Machinery can also undertake all stages of the wood pellet wood pellet manufacturing equipment system project’s design, budget, equipment and material procurement, construction, trial operation and acceptance, and finally submits a project that meets the functions and conditions of use to the customer, and undertakes the quality, progress and cost of the project. and full responsibility for safety.

Steps To Start A Wood Pellet Mill Plant:

Raw Materials

Inspect the quality, price, and quantity of raw materials, and also consider the factors of long-term supply (ie long-term control). According to the raw materials, we can plan the configuration of the production line and analyze the cost.

Wood Pellet Mill Plant Workshop

After determining the raw materials, it is necessary to determine the workshop. The construction or search for the workshop is generally close to the raw materials or a place with convenient transportation. It is the best to have both.

Transformer

The biomass pellet industry consumes a lot of electricity. After determining the production capacity, choose a transformer that matches the equipment power provided by the wood pellet mill manufacturer.

Wood Pellet Mill Machine

Before purchasing equipment, you must first understand the product quality of the wood pellet mills manufacturer. It is often difficult to distinguish the quality of the product in the network environment. You must visit the pellet mill manufacturer on the spot, and don’t be fooled by the low price. High-efficiency biomass wood pellet mill is one of Richi Machinery’s core products.

Installation And Commissioning

We provides free training on the use of industrial wood pellet mills, and assists customers in installation and commissioning throughout the process. Whether you choose your own subcontractor for the erection phase or you want to install everything together with us, RICHI project staff will be around to make sure everything is mounted in a safe and thorough way.

Richi Machinery focuses on wood pellet plant and wood pellet mill for sale, and can provide customers with one-stop, complete set of professional solutions to solve the problems of customers, especially pure investment customers, such as technical difficulties and lack of understanding of equipment, which makes the project more cost-effective.

The needs and positioning are clearer, and at the same time, the customer’s equipment selection range is more concentrated, and the cost consumption such as energy and financial resources is reduced.

RICHI Wood Pellet Mill Process

The processing principle of wood pellets is to pulverize logs or forestry “three leftovers” through a series of processes, and finally form wood chips with a length of less than 3 mm; and then send the wood chips to the industrial wood pellet mill.

Under the condition of high temperature (the wood pellet mill machine operating temperature of the wood pellet mill, no additional heating device is required), the lignocellulose contained in the wood chips can be softened, thereby increasing the cohesive force of the lignocellulose, and under the action of external pressure, the wood Cellulose molecular clusters are dislocated, deformed, and extended, and the adjacent biological pellets inside are bonded to each other, recombined, and pressed into shape.

According to the working principle of the wood pellet mill machine, the raw material processing and production is divided into two main parts, one part is from the pulverization of logs to produce clean and uniform size (less than 3 mm in length) sawdust; the other part is the pressurized granulation and cool, packaging.

The continuous wood pellet mill plant of wood pellets is divided into 4 production sections, namely material preparation section, crushing and drying section, pelletizing section, inspection and packaging section. The material preparation section includes processes such as chipping, wood chip storage, and wood chip screening; the crushing and drying section includes coarse crushing, drying, and fine crushing, inspection, packaging and other processes.

Richi Machinery specially focuses on wood pellet factory construction and wood pellet mill for sale. The design, production, installation, trial operation and other links are fully undertaken by Richi Machinery to achieve full control of each link.

Customers can monitor the progress of the wood pellet mill factory project in real time, and the quality of the project is guaranteed.the construction period is greatly shortened. The following is a step-by-step and detailed explanation of the wood pellet mill plant process.

RICHI Standard Wood Pellet Plant Design

Detailed introduction Of standard wood pellet plant process:

Material Preparation Section

The purchased wood raw materials are generally 1.2-2m in length, 3-8cm in diameter, and 40%-50% in moisture content. Direct crushing will consume a lot of energy. At present, the more mature process is to first go through a chipper to chip. The length of the wood chips (width and thickness are both smaller than the length) should be controlled below 3 cm.

- First, the wood chips are transported horizontally to the magnetic separator, the wood chips without metal are sent to the next section after a 45°turn, and the wood chips and metals with metal are turned by 135°and then sent to the impurity outlet to be removed from the wood pellet mill plant;

- The wood chips after metal removal are sent to the next screening process by vertical wind lifting. During the vertical lifting process, due to the large proportion of sand and gravel, they cannot be transported by the lifting wind, so they will be trapped in this wood fuel pellet plant process;

- After the wood chips are lifted, they are transported horizontally again. In this link, the wood chips need to pass through a filter screen of a certain length. The wood chips larger than the filter screen aperture cannot enter the next wood pellet mill process and will be sent back to the chipper for reprocessing.

- The wood chips containing metal, unqualified wood chips, sand and metal and other sundries in the raw material are all screened and removed in this section, and the qualified wood chips are sent to the coarse pulverizer by the bucket elevator and belt conveyor for pulverization.

Note: The processed wood chips are stored in the wood chip bin through screw conveyors, belt conveyors and bucket elevators. (If the raw material is logs or very thick trunks, you need to add wood splitter equipment; if it is dry sawdust and shavings, after cleaning and magnetic separation, it can be directly sent to the pellet mill for wood);

The processed wood chips usually contain impurities such as soil, sand, and metal, which will cause great wear to the pellet mill for wood; in addition, wood chips longer than 3 cm do not meet the processing requirements of the next section, so an air-selection and dry-cleaning system is added in this section, to remove impurities and screen the wood chips.

Drying Section

After the processing in the material preparation section, the logs have been processed into clean wood chips with a length of less than 3 cm, and the moisture content is generally in the range of 30% to 40%.

In order to further reduce energy consumption and make full use of solar energy, a transparent material preparation shed should be used to centrally store the processed wood chips, and the moisture content of the wood chips should be reduced to 20% to 25% under the conditions of natural light and ventilation. After storage and drying, the wood chips are sent to the crushing system.

- First, the clean wood chips enter the coarse pulverization process of the pulverizing system. Generally, a hammer mill is used, which can pulverize the wood chips to wood chips with a length of 5-6 mm.

- Then, it is directly dried in the pipeline of the channel dryer, and the heating medium of the dryer is clean high-temperature flue gas.

- The dried wood chips are sent to the water conditioning system. The water conditioning system can control the moisture content according to the drying conditions of the wood chips. The moisture content of the wood chips from the water conditioning system is controlled at about 10%.

- The wood chips with qualified moisture content are then ground by a fine pulverizer, and the diameter of the pulverized particles is less than 3 mm, so as to meet the requirements of the industrial wood pellet mill for processing raw materials.

Pelletizing Section

After the wood chips come out of the fine pulverizer, they are directly sent to multiple best wood pellet mills through the distribution bin for granulation. The formed wood pellets pass through the pellet cooling machine and the screening machine, and the unshaped wood pellets are separated from the qualified products and directly sent back to the wood pellet mills for re-granulation.

Packaging Section

The qualified wood pellets are cooled by the pellet cooler machine and then sent to the automatic packaging line. The packaging line adopts automatic bagging machine, which has the advantages of high production efficiency, good packaging quality, and stable weight control. Operations such as shaping have been fully automated, maximizing the efficiency of the wood pellet production line.

Equipment Selection Of Wood Pellet Mill Plant

From customized non-standard models to multi-combination standard models, Richi Machinery not only focus on wood pellet mill for sale, but always in accordance with market trends and customer needs, constantly seeking changes and improving, timely innovation, and adjusting according to customers’ actual processes.

Raw Material Processing And Transportation Equipment

As the raw materials for wood pellet production are fuelwood, shrubs, bark, tree roots, as well as forestry processing wastes, fuelwood processing residues, furniture processing residues, waste wood, veneer, wood chips, waste veneer and other forestry wastes.

Therefore, the production process in the early stage is exactly the same as the production process in the early stage of the wood-based panel, and can be combined according to the material preparation section of the domestic particleboard production line at this stage.

Typical configurations of wood pellet processing equipment include wood splitters, chain wood pullers, belt conveyors, drum chippers, etc. Other equipment can be designed and configured according to the customer’s local resources.

- The raw material is sawdust. If sawdust is added to the raw materials, sawdust feeding equipment, sawdust cleaning (screening machine) equipment and metal removal equipment (removal of metal impurities in sawdust) should be added. Among them, the cleaning device should not only remove large pieces of wood chips mixed in sawdust, but also effectively remove dust. Sawdust can be added at the entrance of the dryer directly into the dryer, or it can be sent to the wet sawdust silo by air, mixed with the sawdust and then entered into the next process.

- Raw materials are furniture processing residues. At this time, special furniture scrap feeding conveyors, drum re-crushing machines, conveyors, etc. should be added. The furniture processing residues must be crushed to become qualified wood chips.

- Add purchased wood chips to the raw materials. Wood chips contain a large amount of soil, gravel, etc. If they are not cleaned, it will seriously harm the main equipment of the subsequent section and affect the final quality of the product. Therefore, wood chip feeding equipment, wood chip cleaning equipment and wood chip transportation equipment should be added.

- The raw material is waste wood. At this time, a template pulverizer should be added, and the screened long boards will be processed into wood chips by a wood pellet hammer mill.

Raw Material Crushing And Drying Equipment

The coarse crushing equipment generally uses a drop-shaped or wide-shaped hammer crusher, and the crushing chamber of the fine crusher adopts the secondary impact crushing technology, which can increase the output by more than 15%.

Changing the position of the hammer on the rotor can form two kinds of hammer screen gaps, so that the raw materials can be crushed evenly. After the hammer is vacuum sintered, its service life can be extended. The wood chip dryer generally adopts a channel dryer, and the drying medium is mostly flue gas.

Pelletizing Equipment——Turnkey Wood Pellet Mill

At present, the mainstream wood pellet mills mainly uses two working principles of flat die and ring die. Production practice shows that the technology of ring die biomass wood pellet mill is more mature, not only the output can be controlled, but also the maintenance and use costs are lower. Are you looking for wood pellet mill for sale? Contact Richi Machinery for details.

Automatic Control System Of Wood Pellet Mill Plant

The automatic control system can automatically control the electrical system of the production line, such as chipping, wood chip conveying, coarse crushing, fine crushing, dust removal, drying and granulation by electric wood pellet mill. According to the characteristics of the wood pellet mill plant, the electrical and automatic control can be divided into four load centers to save cables and reduce energy consumption during long-term operation in the future.

Each load center can use Siemens PLC controller, and the main electrical control components are imported brand Schneider products; the PLC controllers of the four load centers are connected to the upper computer in the central control room through industrial Ethernet communication technology.

Spark Detection (Extinguishing) And Moisture Content Control System

The spark detection and fire extinguishing system, mainly for spark detection or fire extinguishing in the coarse crushing and air delivery system, drying system, fine crushing and air delivery system, dry sawdust silo, dust removal system and pelletizing section of the wood pellet mill plant.

On-line moisture content testing equipment should be installed at the wood chip inlet and outlet of the dryer, and then adjust the wet wood chip feed amount according to the test results, and control the inlet hot air temperature, etc., to ensure that the final moisture content of the wood chips meets the wood pellet production process requirements.

Complete Wood Pellet Mill engineering Design

0.3-1T/H

1.5-2T/H

2.5T/H

6-7T/H

7-8T/H

12-15T/H

15-20T/H

20-30T/H

Richi Machinery is mainly engaged in wood pellet mill for sale, promoting the global strategy, cultivates an international business model, and has accumulated rich practical experience. The customer market covers six continents: Asia, Europe, Africa, North and South America and Oceania.

Why Choose Richi Machinery?

As wood pellet mill manufacturer,Richi Machinery continuous wood pellet production process is comparable to the current mature technology and advanced management concepts in Europe and the United States, and the technology of the early stage of wood equipment introduced at home and abroad is in line with the development trend of wood pellet production technology, so that the wood pellet mill plant has a certain leading edge.

The selection of RICHI wood pellet mill conforms to the current technological development trend, the equipment performance is reliable, the degree of automation is high, and human-machine coordination is emphasized; And select the advanced energy center to achieve the purpose of energy saving and emission reduction; pay attention to the safety performance and fire performance of the production line, which is the best choice for continuous large-scale wood pellet mill plant production.

Horizontal Wood Pellet Mill Vs Vertical Wood Pellet Mill

Some people will look for horizontal wood pellet mill for sale online, and some people will look for vertical wood pellet mill for sale. As a professional wood pellet mill manufacturer, Richi Machinery will objectively compare the two types of products for everyone.

01 Origin

The horizontal wood pellet mills originated earlier than the vertical wood pellet mill and is mature and stable. The horizontal wood pellet mill originated in 1883, and the vertical wood pellet mill granulator originated in Shandong Province, China in the past ten years. Compared with the vertical wood pellet mill machine, the horizontal wood pellet mill machine has a longer service time and higher stability.

02 Applicability of raw materials

The horizontal wood pellet mill has high torque, low speed output, and wide applicability to raw materials. It can be used for raw materials such as high moisture, uneven thickness, and complex types. Vertical wood pellet mills are very “picky” about raw materials.

03 Sealing

The granulation chamber of the horizontal pellet mill for wood is sealed, and all the raw material dust is isolated in the closed space of the ring die to eliminate the phenomenon of ash leakage.

The main shaft of the vertical biomass wood pellet mill is installed vertically, and the dust raw material is in direct contact with the transmission mechanism, which increases the wear of the transmission mechanism.

04 Granulation quality

Due to the large mass of the drive wheel and the ring die, the horizontal biomass wood pellet mill rotates around the axis and generates a large torque relative to the material. During the process, the material is formed at high speed and high pressure to achieve high-quality pellets.

Vertical biomass wood pellet mill is directly bearing with pressure roller, light weight, small relative rotational inertia, slow pressing material speed, and the molding effect is slightly worse than horizontal type.

05 Parts replacement and material blocking maintenance

The door cover of the horizontal wood pellet mill machine is opened on the side, which is convenient to replace the wearing parts. The main shaft of the vertical wood pellet mill machine must be removed to remove the machine, which is troublesome to maintain.

When the horizontal type encounters material blockage or boring machine, it can be cleaned up by shutting down the door and opening the door cover. The vertical wood pellet machine must disassemble all the mechanisms above the ring die to clean it.

In addition, the horizontal biomass wood pellet mill has an overload protection device, which can respond quickly and protect the motor and transmission parts, while the vertical type does not.

06 Pelletizing and molding

The feeding method of the horizontal biomass wood pellet mill is equipped with a forced feeding device, which can force the material into the granulation chamber and increase the filling rate of the granulation chamber. The material is easy to shape. The vertical wood pellet mill relies on the material’s own weight to fall into the granulating chamber.

If the auxiliary materials are uneven or the thickness of the material varies greatly, the material with large mass sinks to the bottom first, and the material with light weight always floats on the top, which eventually leads to the difficulty of the material forming.

07 Service life

The high temperature in the pelletizing chamber of the sealed horizontal wood pellet mill causes the ring die to frequently damage the bearings. The vertical commercial wood pellet mill press roller is installed vertically, due to neutral reasons, the bearings are often burned due to lack of oil.

The above is the difference between the horizontal commercial wood pellet mill and the vertical wood pellet mill. Each has its advantages and disadvantages. When choosing a wood pellet mill or a manufacturer who focus on wood pellet mill for sale, you should purchase the corresponding supporting equipment and determine the model and quantity of the supporting equipment.

Composition Of Wood Pellet Mill Production Cost

01

According to the mature wood pellet mill plant system, the production cost composition includes: local raw material cost (including raw material transportation);

02

Production energy consumption cost;

03

Equipment loss, maintenance cost;

04

Depreciation cost of other fixed assets;

05

Labor cost;

06

Operation and management cost (including tax, sales, transportation, loan repayment, interest payment, etc.).

The components of wood pellet mill plant production costs in different countries are the same, but the specific data and distribution ratios involved are different.

Richi Machinery focuses on wood pellet mill for sale, service process: preliminary investment guidance – plan formulation – equipment configuration – equipment maintenance – equipment maintenance – parts replacement – personnel training and a series of services. If you have any related questions, please contact Richi Machinery directly.

Supplementary Information Of Wood Pellet Production

What Is Wood Pellets?

Wood pellets refers to the use of forest tending and felling residues, as well as wood processing residues, sawdust, bark, etc. as raw materials, under high pressure (49-196MPa) and heating conditions, compressed into granular and solid moldings , its density can reach 1.1-1.5 t/m3, and its calorific value can reach more than 4500 kcal/kg. It has combustion characteristics equivalent to secondary bituminous coal, and its ash content is less than 1.5%.

Generally, the wood pellet mill is suitable for molding when the moisture content is 12%-15% and the size of the raw material before enter in the wood pellet mill machine is less than 5 mm.

Richi Machinery can provide you with a single poultry feed pellet machine and a complete set of poultry feed plant equipment and solutions. Product-proficient, skilled and experienced service engineers are ready to go, ready to provide you with meticulous and considerate services to meet your needs!

Factors Affecting The Wood Pellets Quality

Factors affecting the output quality of industrial wood pellet mill:

01 Tree Species

The chemical composition, cellulose content and calorific value of different species of wood will affect the quality of wood pellets. Among them, the calorific value is also very different depending on the tree species and their proportions.

Different tree species have different wood fibers. The wood of tree species with fine fibers has good flexibility, good shape of sawdust, and is easy to be pelletized by wood pellet mills, such as poplar, pine, etc.; tree species with thick fiber have poor flexibility, the sawdust is broken, and pelletizing is difficult to shape.

02 Wood Density

Sawdust with low wood density has good plasticity and is easy to form.

03 Wood Moisture Content

The moisture content of wood has a great influence on the production of wood chips. With high moisture content, the wood is easy to stick in the wood pellet hammer mill , and the output decreases rapidly. The moisture content of wood chips before pelleting should be controlled between 10% and 15%, otherwise the pellets will burst due to excessive internal steam.

04 Production Equipment

Wood pellet mills are key factor affecting the quality of wood pellets, especially wood pellet mill machines, wood pellet hammer mill and wood dryers. Their mechanical properties have a great impact on the output of the wood pellet mill plant and the quality of pellets.If you are looking for wood pellet mill for sale, find Richi Machinery.

Richi Machinery always adheres to customer-centricity, using new technology to make products from every tiny component to the whole wood pellet plant machine, have a strong technical guarantee and build core competitiveness!

The Raw Materials requirements Of Wood Pellet Mill

The requirements for the raw materials of the biomass wood pellet mill directly affect the quality of the wood pellets. Only by controlling the raw materials can high-quality pellets be made. So, what are the requirements for raw materials when the industrial wood pellet mill is pelletizing?

01 Material Size

When the electric wood pellet mill is granulated, the size of the raw material is required. Generally, the size of the raw material after crushing must be less than 5MM.

The specific crushing size is also determined according to the expected diameter of the pellets and the size of the diameter of the electric wood pellet mill die. If the raw material is crushed too large or too small, it will affect the output and quality of the pellets, and even cause no material.

02 Raw Material Moisture

When the wood pellets are granulated, there are also strict requirements for moisture. No matter what kind of raw material, the moisture must be controlled within 12-18%. If the moisture is too large or too small, the pellets will be easily broken or loose.

03 The Raw Material Completely Gets Rid Of The Sticky Agent

There is no need to add any binder when making wood pellets, because wood chips themselves are a kind of crude fiber raw material and have certain adhesiveness. Then it can be formed naturally after being squeezed by the wood pellet machine.

Don’t be afraid if you encounter raw materials without adhesiveness, RICHI ring die wood pellet mills can help you. This biomass wood pellet mill can produce strong pressure due to its special structure, and it is the nemesis of difficult-to-form raw materials. The resulting pellets are dense and smooth.

04 Different Raw Materials Can Be Mixed For Wood Pellet Mills Granulation

The pellet mill for wood is not only able to use one kind of sawdust for pelleting, but also can be mixed with other kinds of sawdust. In general, it can also be mixed with crop straw, fruit shell, peanut shell, straw and so on.

The pellets made by mixing other varieties of sawdust are still high-quality pellets, and the pellets mixed with straw, because the quality of the straw itself is not as good as that of the sawdust, the quality of the pellets will be slightly lower, and at this time, it cannot be called wood pellets but straw pellets.

05 Do Not Be Afraid Of Mildew Of Raw Materials

Sometimes there are more raw materials collected, and if they are not used up for a while, the raw materials will be mildewed and blackened. At this time, the pressed pellets cannot reach the required density and heat, and it is a pity to throw them away.

There is no need to worry about the mildew of the raw materials, as long as we add more than 50% of the fresh raw materials, the more new raw materials are added, the higher the quality of the pellets will be. The specific situation depends on the customer’s needs.

Richi Machinery always adheres to customer-centricity, using new technology to make products from every tiny component to the whole wood pellet plant machine, have a strong technical guarantee and build core competitiveness!

Wood Pelletizing System From Richi Machinery

In the past 30 years, as wood biomass pellet mill manufacturer, we have accumulated rich experience. We has exported wood biomass pellet mill for sale the world, and has reached cooperative relations with more than 1,000 customers in more than 120 countries and regions, providing them with complete solutions and services covering the entire product life cycle.

Richi Machinery’s wood pellet mill plant solution is not a repetitive superposition of construction contracts in the general sense. It is an in-depth integration of various stages of work such as design, procurement, construction, and trial operation, improving project construction efficiency and ensuring project construction progress.

Richi Machinery focuses on wood pellet plant and wood pellet mill for sale, as a professional wood pellet mill supplier, in fact, Richi Machinery does not only regard wood pellet plant as a “turnkey project”, we hope it is a key to entering the new model of whole pellet plant project management, and jointly maintain the stable and healthy development of the market.