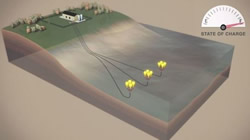

Energy Storage in Underwater Balloons

Tom Lombardo for Enegineering.com: Grid-level energy storage takes many forms, including flow batteries, Li-ion batteries, pumped hydro, compressed air in underground caverns, and even flywheels. Toronto’s Hydrostor just added another tool to the arsenal: underwater compressed air energy storage (UCAES). Hydrostor recently activated a pilot UCAES plant - the first of its kind - that will provide grid-level storage for the city of Toronto. In addition to supplying the city with cost-effective energy storage, the system will allow engineers to study its behavior and optimize the design. Can UCAES become a viable energy storage technology?

Tom Lombardo for Enegineering.com: Grid-level energy storage takes many forms, including flow batteries, Li-ion batteries, pumped hydro, compressed air in underground caverns, and even flywheels. Toronto’s Hydrostor just added another tool to the arsenal: underwater compressed air energy storage (UCAES). Hydrostor recently activated a pilot UCAES plant - the first of its kind - that will provide grid-level storage for the city of Toronto. In addition to supplying the city with cost-effective energy storage, the system will allow engineers to study its behavior and optimize the design. Can UCAES become a viable energy storage technology?

The idea has been around for many years: when supply exceeds demand, use the excess energy to run an air compressor and store the air in an underwater balloon. When power is needed, open a valve and let the compressed air run a turbine to generate electricity. The principle is simple, but the economic feasibility has yet to be demonstrated. Hydrostor hopes that their facility becomes the proving ground. Cont'd...

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product