Tesla Patents New Process To Bond Solar Cells With Heat-Cured Conductive Adhesive

Steve Hanley for CleanTechnica: Business as usual is not the usual for Elon Musk. He and his minions are always looking for new and innovative ways to disrupt the status quo. A solar panel consists of lots of solar cells that all have to be interconnected, usually by soldering or placing them in a convection oven. But business as usual is not usual in any business Musk is connected with.

Steve Hanley for CleanTechnica: Business as usual is not the usual for Elon Musk. He and his minions are always looking for new and innovative ways to disrupt the status quo. A solar panel consists of lots of solar cells that all have to be interconnected, usually by soldering or placing them in a convection oven. But business as usual is not usual in any business Musk is connected with.

Prior to being acquired by Tesla, SolarCity filed a 28 page patent application that covers a new way of manufacturing solar panels using a heat-activated adhesive that also conducts electricity. The conductive thermo-setting adhesive may be unique — and apparently it is — but the process will be familiar to anyone who has ever watched hamburgers being cooked at Burger King.

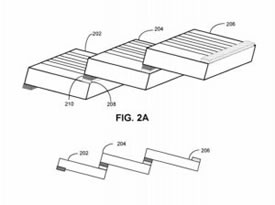

The solar cells are arranged in a cascading arrangement, then placed on a moving belt that takes them for a trip beneath the specially designed heaters. When they pop out the other end of the line, they are permanently bonded together. SolarCity claims in its patent application, which is entitled “Systems, Method, and Apparatus for Curing Conductive Paste,” that the process is more efficient than conventional manufacturing methods. Full Article:

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product