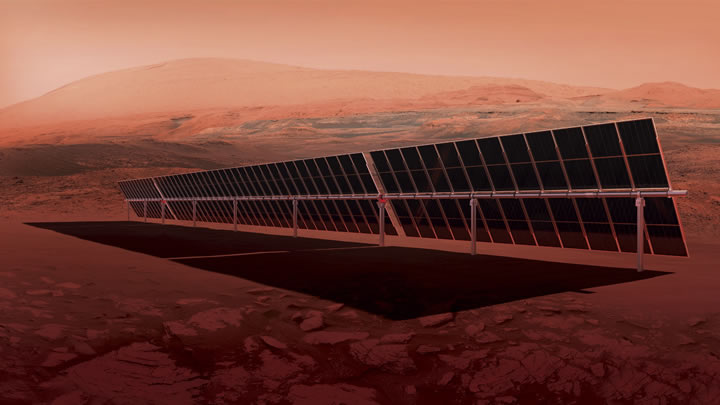

Soltec launches the SF8, the largest single-row tracker on the market

Soltec, leading manufacturer and supplier of single-axis solar trackers worldwide, presents its new SF8 tracker. Under the slogan “engineered for greatness”, the SF8 tracker aims to revolutionize the photovoltaic market with its new minimum 2x60 configuration and 4 to 6-strings.

This elegantly designed tracker reinforces its structure to facilitate installation and favors high performance on any terrain. A reinforced torque tube with a new, improved geometry, together with an autonomous self-stow system, contribute to increased tracker resistance to adverse weather conditions. In addition, the SF8 tracker increases the rigidity of its structure by 22% more than the previous generation of Soltec trackers, the SF7. “We have made use of all our acquired knowledge, in collaboration with RWDI, to design the most robust tracker in the marketplace”, states Sergio López, Soltec’s COO.

The SF8 is specially designed for larger 72 and 78 cell modules, an increasing market trend. “As tracker manufacturers our designs adapt to market trends with the aim of providing clients with the best performing trackers”, explains Raúl Morales, Soltec’s CEO.

The SF8 has 5.16% fewer parts per module than the previous generation of Soltec trackers, thus increasing cost and installation efficiency. Each SF8 tracker is equipped with, at least, 4 strings, contributing to ease electrical module connections. Due to these innovations, the SF8 allows for easier and quicker installation, favoring enhanced return on investment and reduced installation and maintenance costs.

Smarter, Greater Bifacial Yield

The new SF8 has an innovative full-wireless system allowing complete plant and inter-tracker connection. The Open Thread system developed by Google contributes to improved plant protection and to preventing damages by accurately anticipating weather conditions.

Compared to competitors, the revolutionary technology of the SF8 tracker allows up to 8.6% more power generation when bifacial modules are installed. “With the TeamTrack system, Soltec was already capable of producing 6% more energy. Now we have improved and adapted this algorithm to bifacial modules, for an extra yield of up to 0.5%. This extra Bifacial Gain of SF8 trackers adds to the 2.1% of Bifacial Gain yielded by our bifacial tracker in comparison to 1-in-portrait configuration trackers of competitors”, says José Alfonso Teurel, CTO at Soltec Innovations.

“We think our SF8 will revolutionize the solar tracking market. Its 2x60 minimum configuration will not only reduce installation and maintenance costs, it will also yield more energy and increase overall photovoltaic plant performance. At Soltec we are very pleased with both this development and the optimization it will bring about in terms of power generation in large photovoltaic parks”, concludes Raúl Morales, Soltec’s CEO.

More info about this product at: https://soltec.com/sf8-single-axis-tracker/

SOLTEC

Soltec is the third manufacturer and supplier of solar tracking equipment for photovoltaic plants worldwide. Founded in Murcia, Soltec is part of Soltec Power Holding, employs over 1,600 professionals and has 16 years’ experience in the manufacture of complete solar tracking systems. The company operates in Argentina, Australia, Brazil, Chile, China, Denmark, Egypt, United States, Spain, India, Italy, Israel, Mexico and Peru. More information at: https://soltec.com/

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product