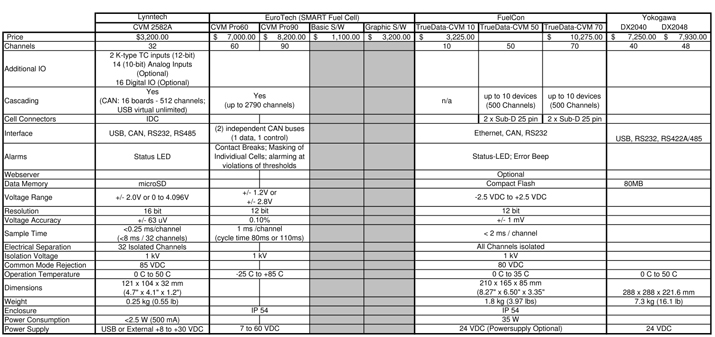

Knowing what's happening inside a fuel cell is a critical function, especially as fuel cells are continuing to be developed. One important aspect of this is to measure the voltage of each cell in a stack. Although this may sound trivial, it can be more complex and more expensive than it may at first appear due to high voltages, high channel counts, communication types, etc. There are a few products commercially available that are designed specifically for fuel cell voltage monitoring.

Daniel Westerheim | FuelCellsEtc.com

The content & opinions in this article are the author’s and do not necessarily represent the views of AltEnergyMag

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product