What Solar Energy Developers Need to Know

Is Ontario's Solar Sector Growing too Fast ?

A. Keranovic | The Solar Gazette

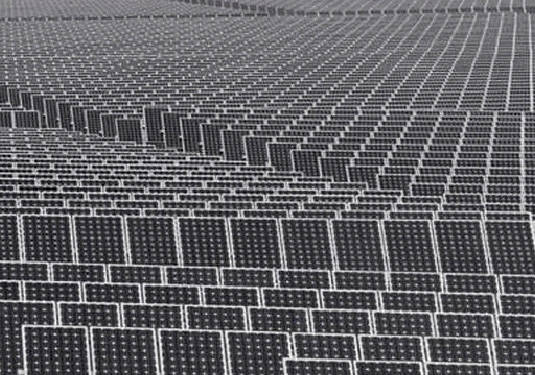

Since the recent implementation of North America’s first renewable energy Feed In Tariff program, the Ontario government has awarded close to 3,000 megawatts of solar Power Purchase Agreements, representing over 13 million individual solar panels to be installed across the province in the immediate future. But this explosive growth combined with the region’s lack of supporting skilled labour is expected to leave several clean energy projects literally in the dust.

“The immense amount of solar energy parks all simultaneously going into construction is disproportionate to other necessary stakeholders in the sector, setting the stage for what could potentially become a very big blemish for the program ” stated Michael Petrova, President of Solar Clean (solarclean.ca), an established solar maintenance company offering professional services across the province.

“It’s important that solar energy developers entering into the province realize that maintaining solar panels is a lot different than cleaning windows…if this is not realized, the effects could not only impact their bottom line, but could potentially be fatal ” added Petrova.

Unlike regular cleaning services, Mr. Petrova proudly points out that his employees are trained in how to work safely with water around high voltage systems, the use of safety equipment such as fall arrest systems, operating elevated devices and ladder safety techniques, electrical hazard awareness, as well as how to spot and repair operational deficiencies which could potentially turn into hazards leading to system down time and lower yields.

Manufacturer studies show that a clean solar panel produces up to 30% higher energy yields than an unkempt panel, which means significant higher returns on investment for responsible developers and on time pay back for financiers and investors. Therefore regular maintenance is not only recommended, it’s mandatory.

Potential lost revenues of this magnitude should be expected to put unseen pressures on solar park operators. Energy producers working on low operating budgets or who simply cannot find qualified maintenance crews due to lack of availability may be tempted to put unskilled labourers in place, leaving not only the hired help at risk, but also potentially putting their entire operation in jeopardy.

Project owners need to check their insurance policies to see exactly who is insured on their roofs and solar farms - Better yet, are strongly recommended to only contract qualified maintenance crews who have their own insurance policies in place, specific to the assignment.

Brent O’Connor, from Geneva Bancorp- a Monaco based investment banking firm who has participated in the funding of several utility scale solar energy projects in the province commented “Experienced project financiers will want to see a budget of approximately 3% of the total project cost in place to be appropriated towards regular maintenance upkeep before inking a deal… additionally, savvy financiers may insist that maintenance crews are qualified and that they not only have their own insurance in place, but also adhere to solar panel manufacturer warranty policies to protect their investment.”

The chance of a void warranty claim occurring on equipment due to not adhering to the manufacture’s recommendations is a valid concern while choosing a maintenance program. Something as simple as using the wrong cleaning solution on panels could potentially void the warranty on an entire park- a potential multi million dollar mistake.

Charles Mazzacato, VP of Atlantic Wind & Solar Inc., a thriving Toronto based company involved in over 100 large scale commercial rooftop solar energy parks stated “Engaging in a quality operating and maintenance program can be as an integral part of the system as the type of panels and inverters applied.”

But what exactly does a comprehensive solar maintenance program consist of? Panels are exposed to a number of elements, leaving them susceptible to dirt, dust, pollen, bird droppings, acidic precipitation and other debris in the air. The cleaning of these remnants in a safe, thorough manner, while utilizing eco-friendly, manufacturer approved cleansing products is only a small part of the necessary routine.

Regular, thorough inspections for potential cracking of lenses, deficiencies in racking, loose electrical connections, the realignment of panels due to excessive snow loads, the inspection and alignment of tracking systems and the prevention of vegetation causing shading should also be included in a reliable program.

Many leading solar developers in the province feel that allocating 4-6 maintenance visits per annum is sufficient, while other companies believe in several more. The scheduling should place emphasis on the months where the dust and pollen are most prevalent, while altogether eliminating visits during the winter months where rain and snow can potentially substitute a cleansing.

Ontario’s shift towards renewable energy is precedent setting, and when approached in a safe and wise manner, the results will deliver a lot of wealth and success into the hands of educated stakeholders.

But be forewarned, without the proper amount of due diligence exercised, the potential consequences will leave some unprepared entrepreneurs with nothing but a big mess to clean up, while facing serious repercussions.

The content & opinions in this article are the author’s and do not necessarily represent the views of AltEnergyMag

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product