Wind gusts can increase wind speeds at rates and for durations just long enough for the energy to enter the system, but sometimes too fast for conventional pitch control systems to respond adequately.

Power Regulation and Pitch Control

Wes Illing | WindKing Technologies

In 1903 the Wright brothers demonstrated to the world the tremendous power of the modern airfoil. By the 1920’s the demand for electricity in modern countries was skyrocketing. Man had been successfully using drag plates for about a 1000 years on windmills to pump water and for centuries to mill grain. Replacing the inefficient drag plate with the modern airfoil and adding an electric generator seemed a sure winner. However, so powerful and efficient was the airfoil, until 2015 the wind industry has never been able to adequately regulate its power output when subjected to the common wind gust.

Power Regulation is the key to not only reducing O&M costs and increasing design life, but more importantly to increasing AEP (Annual Energy Production). Many manufacturers chose smaller rotor diameters to mitigate the damage caused by the common wind gust. Often these systems can’t reach full power until wind speeds reach 25-30 MPH. This was a very smart compromise. Unfortunately, it often makes wind energy more expensive and without incentives, competing with existing wholesale energy providers is difficult.

Wind gusts can increase wind speeds at rates and for durations just long enough for the energy to enter the system, but sometimes too fast for conventional pitch control systems to respond adequately. For decades, component manufacturers have often been blamed for failures in transmissions, generators, slip rings, and more recently inverters. The inability of turbines to regulate power intake in real time has been problematic.

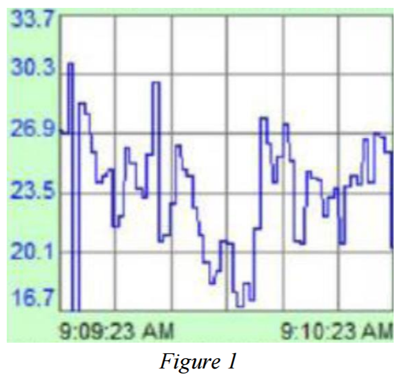

It seems silly, but in all fairness the evidence is counter intuitive. The nature of wind gusts is well illustrated by the screen shot in Figure 1 taken on a nice, breezy but not stormy day. The vertical axis in Figure 1 is wind speed in MPH and the horizontal axis is 1 minute in duration broken into 10-second intervals. The screen was limited to a 50- millisecond update speed, so the real wind speed measurements were clipped giving an appearance of being step functions instead of variable ramp functions. Nice sinusoidal wind speed variations, as one might imagine, did not exist. Real wind speed variations most closely resemble a complex ramp function.

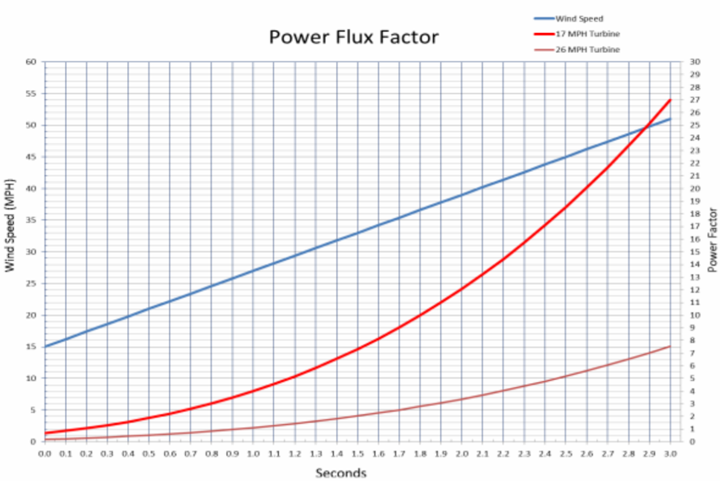

When a common wind gust as illustrated in Figure 2 passes through the rotor of a turbine, available power increases with the cube of that increasing wind speed. The highly efficient airfoil responds like a sail on a boat and it takes off when the wind gusts. Figure 2 compares the energy available to a turbine with a rotor diameter reaching full power at 17 MPH to a rotor diameter reaching full power at 26 MPH. The axis on the right depicts the power factor. In other words, for the common 3 second ramp function example, how quickly does the wind increase power flowing through the plane of the rotor by a factor of 1 times the rated generator power? Clearly, a turbine designed to reach full power at 26 MPH has more time to respond to gusts than a turbine designed to reach full power at 17 MPH. As illustrated, about 2 seconds into the gust, the 17 MPH turbine can increase its power output by one full power factor (100% of its rated power) in as little as 100 milliseconds, while the 26 MPH turbine only increases its power output by about 66% of its rated capacity over 200 milliseconds. Unfortunately, even a 66% increase in power over a 200-millisecond period can contribute to fatigue failures.

Due to sensor response time, signal conditioning, raw data processing needs, control algorithm response time, the response time of the pitch motors, and the pitch axis inertial delay imposed by the blades themselves, 200 milliseconds is just too short a time. If existing pitch control systems were designed to respond this fast, stability problems and excessive wear can prevail.

Historically, we have assumed controlling pitch angle positions with an active pitch angle control system would provide power regulation AND maximize our AEP. Now new test results, as illustrated in Figure 1 and applied in Figure 2, indicate the elegant Betz equation is very unforgiving when applied to real world transient wind gust phenomena. Real time power regulation requires a pitch control technology to reduce power intake without ANY delay. Regulating Power and Maximizing AEP are two very different technical objectives.

A power regulation system capable of responding without any delay was recently developed and field tested for a 17 MPH turbine. During very tough wind gust transients, when power intakes should have increased 50 fold, power output stayed within 15% of the rated power. This Advanced Pitch Control technology uses an RPM based pitch control approach rather than a position based pitch control. Its first priority is Power Regulation which is a function of rotor RPM and its second priority is Pitch Angle optimization for maximizing AEP. The change in the mechanical configuration of the final pitch control elements in order to introduce a new term in the differential equations governing their behavior, frees the system of any time delay for Power Regulation. It also allows changes of the power in the wind to transfer into the rotor and directly change the pitch angle. The faster the power in the wind changes, the faster the pitch angle changes.

Eliminating time delays with real time power regulation, pitch angle slew rates were not much faster than they have been historically, the pitch angles just began changing much sooner. Perhaps most significantly, this Advanced Pitch Control technology demonstrated its ability to work WITH the wind gust. The bigger the wind gust was, the faster the power intake dropped. Noteworthy was confirmation that a change in the disturbance of the Betz flow field, as produced by a significant pitch angle change, does not need to propagate through the entire Betz flow field to adequately change the power intake.

Consequently, rotor diameters can now be increased considerably, so full power can be reached at much lower wind speeds (ie 15-17MPH). This means lower start-up speeds and full power output a much greater percentage of the time. Substantially increasing AEP by more than a factor of 2 offers the most substantial impact on the bottom line for all wind turbines and especially wind farms already operating under tight profit margins. As an added bonus, this can be done within a wind farms’ existing electrical infrastructure, since rated power need not increase. Unfortunately, retrofitting existing turbines will not be cost effective. They will need to be replaced, including both the nacelle and tower components, as well as the controller.

In addition to reducing O&M costs, wind farms need to remain competitive with declining wholesale rates for electricity. Significant increases in AEP may offer them their most promising path forward.

WindKing Technologies is currently developing strategic partners to commercialize its disruptive technology platform.

The content & opinions in this article are the author’s and do not necessarily represent the views of AltEnergyMag

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product