Working with partners in industry and academia, NREL delivers the scientific building blocks for new energy technologies that drive the country's economic growth. NREL's world-class researchers, facilities, tools, and analysis yield innovations that create new business opportunities and greatly reduce the risk of investment for energy companies and manufacturers.

NREL at 40: Research Efforts Drive Advanced Energy

Contributed by | NREL

Sheila Hayter, Manager of NREL's Strategies and Implementation group, and Kenny Gruchalla look at a community energy grid model in the ESIF's Insight Center Visualization Room. Efforts to improve the security of the electrical grid are underway at NREL. Photo by Dennis Schroeder

As July marks the 40th anniversary of the U.S Department of Energy's (DOE) National Renewable Energy Laboratory (NREL), an energy revolution is sweeping the nation, creating new opportunities for American workers, driving innovation, and ensuring U.S. energy security. The laboratory is poised to lead America into the future—for the next 40 years and beyond.

Working with partners in industry and academia, NREL delivers the scientific building blocks for new energy technologies that drive the country's economic growth. NREL's world-class researchers, facilities, tools, and analysis yield innovations that create new business opportunities and greatly reduce the risk of investment for energy companies and manufacturers.

Building on decades of work and ongoing advanced-energy research, today's NREL tackles a range of energy challenges with an integrated approach. It seeks ways to strengthen the U.S. manufacturing sector through on-site production of wind turbines and continues to enhance the solar technologies industry with disruptive innovation. NREL partners with utilities to help to secure the nation's energy grid and is leading teams that develop cost-competitive, domestically sourced products like ammonia for fertilizer, ethylene for plastics, and acrylonitrile for carbon fiber. The laboratory stands at the forefront of integrating biomass into the nation's petroleum infrastructure.

NREL's longstanding mission is reaping benefits. The laboratory gives U.S. entrepreneurs a competitive edge in the global energy race by bridging the gap from concept to market. In fact, NREL is the only national laboratory that regularly links research and development (R&D) with real-world applications.

"We continually look forward," said Martin Keller, who joined the Colorado laboratory as its ninth director in November 2015. "Our leading-edge research is informed by world-class analysis that reveals gaps in technology and market needs. This innovative approach delivers value to American industries and creates economic opportunity for the nation in the form of energy security and prosperity."

Looking to the Sun for New Forms of Energy

NREL researchers David Moore and Obadiah Reid are producing perovskite crystals like this one, illuminated in their laboratory at NREL's Solar Energy Research Facility. Photo by Dennis Schroeder

The early 1970s witnessed long lines and high prices at gas stations—the result of an embargo that dramatically shrank the amount of oil imported by the United States. Three months after his 1977 inauguration, President Jimmy Carter announced his intention to reduce dependence on foreign oil and invest in alternative energy sources. He created the Solar Energy Research Institute (SERI) with the mission to launch a new American energy industry and he consolidated oversight of U.S. energy policy into the newly formed U.S. Department of Energy.

While early work at SERI concentrated on solar technologies, the focus quickly broadened to include many forms of advanced energy, including wind and biomass. In 1991, President George H.W. Bush elevated SERI to a member of the DOE's national laboratory system and changed its name to the National Renewable Energy Laboratory.

Decades after Carter began his push for solar, renewables provided more than 60% of new U.S. generating capacity last year. DOE estimates that energy and energy-efficiency work employs nearly half a million Americans today, much of this growth is fueled by advanced energy technologies such as wind and solar. The nascent solar industry that NREL helped get off the ground in 1977 now employs 73,000 Americans, and its hiring rates are outpacing U.S. economic growth by up to 17 times. With a steadily increasing amount of solar power added annually and a single gigawatt (GW) having the ability to power 700,000 homes for a year, the nation is expected to produce 330 GW of electricity from photovoltaics (PV) by 2030—more than enough to serve the nation's 126 million households.

"PV is now a business," said Greg Wilson, co-director of the National Center for Photovoltaics at NREL. He joined the laboratory in 2011 after spending almost 25 years in industry. "One can argue that PV is growing at such a rate that it's on its way to becoming mankind's largest enterprise in the next decade."

Two factors drive the adoption of solar power: PV system price (how much it costs to generate each watt of electricity), and efficiency (how good a job a panel does at converting sunlight into that electricity) which ultimately impacts system price and makes some PV technologies more value when space is limited. Advanced research at NREL could disrupt the global solar market as the laboratory explores PV absorber materials beyond silicon, as well as new device designs and processing techniques that can further improve both the cost and performance of silicon cells.

Looking for New Materials to Capture Energy

Perovskites, for example, stand out as a promising path to low-cost, high-efficiency solar panels. The crystalline material, lighter and thinner than silicon and easier to produce, has astounded researchers with its rapidly improving efficiency. Since scientists began studying perovskites in 2009, efficiency has soared to 22% from slightly less than 4%, but challenges remain before perovskite solar panels reach the marketplace.

"We have very high efficiencies but the cells are not yet stable enough," said Jao van de Lagemaat, director of NREL's Chemistry and Nanoscience Center. "However, research at NREL and across the world is driving the technology to be far more reliable."

Perovskites also could help wrest some of the solar market from China, where a silicon supply chain exists that's lacking in the United States. Perovskite solar cells could be applied to a flexible roll of film similar to how newspaper is printed, skipping the costly manufacturing process silicon panels require.

"To really disrupt a maturing market you have to be really different and offer something that totally changes all assumptions," van de Lagemaat said.

Another potential game-changer developed through NREL research is a carbon nanotube thin film with the potential to act as a thermoelectric power generator that captures and uses waste heat. More than half of the energy consumed worldwide is rejected primarily as waste heat, so a path to recapture some of that lost energy is emerging as important research. The lightweight, flexible film could be used to recharge portable wireless devices, or could even be woven into fabrics, allowing wearers to generate power simply by moving around.

Preparing for the Modern Electrical Grid

The electrification of the United States stands out as the single greatest engineering achievement of the 20th century. For the 21st century, however, there's more work to be done. Major efforts to improve the security of the electrical grid are underway at NREL.

The grid is starting to evolve as electricity generation sources become more diverse. For more than a hundred years, utilities have mostly relied on large power plants (fueled by coal, nuclear, or natural gas) to supply the country's electricity needs. Today, the amount of advanced energy from sources such as wind and solar is growing rapidly, accounting for 64% of U.S. electricity capacity additions in 2015.

Wind turbines and solar panels are very different from traditional power plants because they do not produce power all the time, but utilities still must ensure electricity is always available. As a result, the grid must become more flexible and collect more data—it must become smarter.

Research into how these devices—and energy sources—can be connected to the grid happens at NREL's Energy Systems Integration Facility (ESIF). Laboratories within the ESIF connect to a megawatt-scale microgrid to determine how everything would communicate and work together. NREL's grid modernization efforts ensure security and reliability, and a resilient way to efficiently power homes and communities.

A grid in which utilities and devices communicate opens the door to cybersecurity threats, however. Natural disasters, which can trigger power outages, are already testing the grid—but hackers pose an unpredictable risk as well. NREL research aimed at thwarting hackers goes so far as developing technology to cloak the network from unauthorized users.

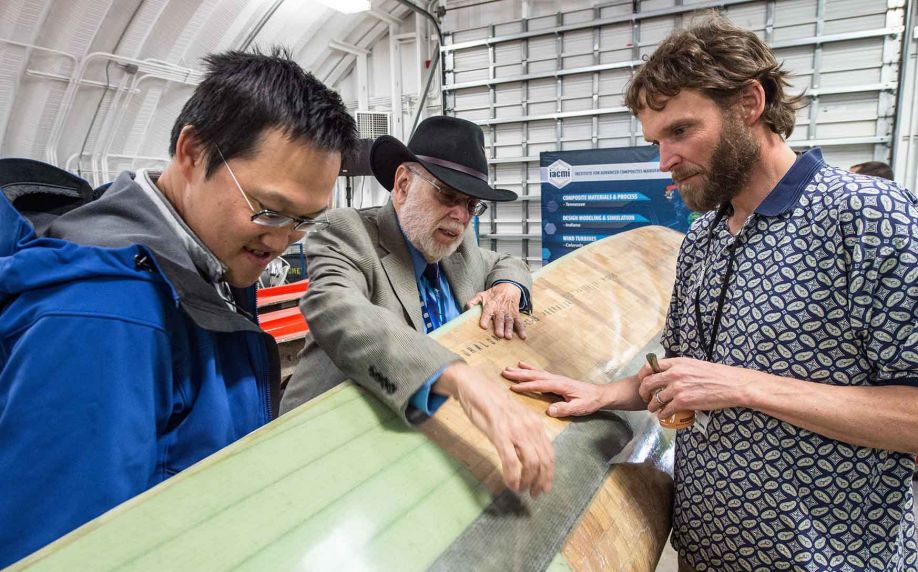

Attendees get a closer look at a wind blade in the new CoMET facility at NREL’s NWTC. The 10,000-square-foot facility will be used to develop innovative wind turbine components and will serve as a workforce development resource for the growing U.S. composites manufacturing industry. Photo by Dennis Schroeder

Opportunities for Local Manufacturing

Wind is surpassed only by hydropower when it comes to the percentage of electricity generated by renewable sources in the United States. A gap exists, however, in where wind turbines can be found. The southeastern part of the country lacks turbines, but new NREL research could increase their presence there and elsewhere by overcoming manufacturing and transportation challenges. As turbine manufacturers build bigger and bigger blades, getting them to the installation site becomes more difficult.

"When I joined the wind industry in 1995, we were still producing 9-meter blades," said Derek Berry, senior wind technology engineer at NREL. "You could put about 27 of them on a truck and ship them wherever we wanted to. Eventually we started manufacturing 20- and 30-meter blades and we were still able to ship them without much trouble. As we began producing wind turbine blades that were 50 meters and longer, we encountered increasing obstacles in transporting these massive structures."

The solution may be in manufacturing blades at the installation site, using lessons to be learned at the Composites Manufacturing Education and Technology (CoMET) facility, which opened in February at NREL's National Wind Technology Center (NWTC). The longer the blade, the more energy a turbine can capture and the less it costs to generate electricity. But long blades must be lightweight. Various composite materials and manufacturing processes will be evaluated at the new center to determine what might work the best, from balsa wood and fabric to carbon fiber and resins. Researchers using the CoMET facility will be able to design, fabricate and validate prototype blades.

The ability to build turbines on-site will only increase the number of jobs in an industry that already employs more than 100,000 people. In addition to manufacturing jobs, the number of turbine technicians is expected to more than double over the next decade. By 2030, as many as 380,000 people could be working in the wind industry nationwide—including areas ranging from the southeast up through mid-America.

Creating a Market in the Heartland

Biomass is currently the greatest single source of renewable energy in the United States representing 3.9 quadrillion British thermal units in 2015. And, according to DOE, there are more than 156 million acres of agricultural waste produced by our nation's farms. These non-food crop residues—corn stover, cereal straws, and sorghum stubble—can be used to build an industry for the production, manufacture, and distribution of fuels, chemicals, and other products across the country.

Questions remain about how to mobilize these resources. NREL's bioenergy R&D touches every point along the biomass conversion process, from basic science to mobilizing resources through transferring technology to industry. Work on microbes and enzymes has helped reduce the cost of producing cellulosic ethanol by 67%. NREL's thermochemical and biochemical pilot plants have provided scale-up test beds to perfect conversion processes. Such technology has played a significant role in helping DuPont and POET open cellulosic ethanol biorefineries in Emmetsburg and Nevada, Iowa.

Today, NREL is adding capabilities to produce domestically sourced drop-in hydrocarbons that are compatible with petroleum infrastructure, as well as high-value, cost-competitive, bio-based chemicals and materials that reduce carbon demand.

Ethylene for plastics is an example of NREL's innovative research in bio-based chemicals. Made most often from petroleum and natural gas, ethylene is used in the manufacture of plastics and polyester, and ranks as the most-produced chemical by volume in the world. But the process of making ethylene requires considerable amounts of energy and releases carbon dioxide (CO2) into the atmosphere.

"We envision some farms in the field that cover many acres," said Jianping Yu, a research scientist in NREL's Photobiology group. "We will have cyanobacteria harvesting sunlight and CO2 and then producing ethylene or ethylene derivatives. That's pretty far from where we are now, but that's the goal. If things work out, 10 years from now we should see some farms making petrochemical replacements."

NREL scientist Jianping Yu holds cyanobacteria cultures being grown in his laboratory. He is working to cultivate various genetic strains to promote ethylene production. Photo by Dennis Schroeder

NREL Leads America's Advanced Energy Future

For 40 years, NREL has expanded American prosperity and security through world-class research. The laboratory's work stimulates the U.S. economy, inspires ingenuity, and preserves our nation's energy security.

"Innovation leads to job creation and economic growth," Keller said. "We are increasing our attention on science that has market-relevant potential. We are expanding our pursuit of new techniques in advanced manufacturing and advanced materials. And, we are focusing our energy systems integration efforts to design advanced meters, inverters, sensors, and controls for a future grid that is agile and responsive."

Regarding the future, Keller says: "We at NREL, along with our partners in industry and academia, intend to keep pushing forward to produce innovative ideas that will help meet the country's energy needs."

The content & opinions in this article are the author’s and do not necessarily represent the views of AltEnergyMag

Comments (0)

This post does not have any comments. Be the first to leave a comment below.