One goal of nanotechnology is to improve photovoltaic solar electricity generation. The thermodynamic limit of 80% productivity is well beyond the capabilities of current photovoltaic technologies, whose performance now is only about 43%.

Capturing Energy with Nanotechnology

Len Calderone for | AltEnergyMag

Can using nanotechnology in the efficient capture of sunlight and its conversion to electricity drive economical fuel production processes? Engineers at UC San Diego have developed a nanoparticle-based material for concentrating solar power plants that converts 90% of captured sunlight to heat. With particle sizes ranging from 10 nanometers to 10 micrometers, the multiscale structure traps and absorbs light more efficiently and at temperatures greater than 700 degrees Celsius.

The multiscale structures can catch and soak up light, which contributes to the material's high proficiency when run at higher temperatures. This new market of concentrating solar power is an ideal alternative for clean energy. It can produce roughly 3.5 gigawatts of power, which is sufficient to power more than 2 million homes. Since it uses the same process as existing power plants, it can be used as a retrofit for existing power plants.

One of the most common types of concentrating solar power systems uses more than 100,000 reflective mirrors to direct sunlight at a tower that has been painted with a light absorbing material. The material is designed to maximize sun light absorption and minimize the loss of light.

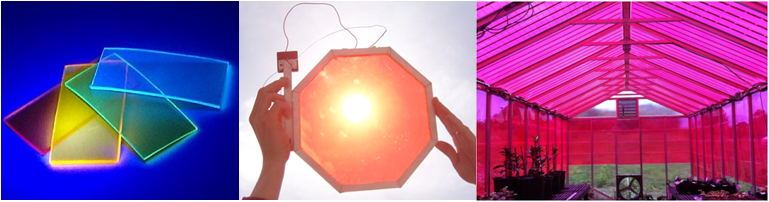

A small type of concentrator can capture sun light for local usage. A luminescent solar concentrator is a sunlight harvesting technology that changes the way we think about energy. It could turn any window into a daytime power source. In these devices, a fraction of light transmitted through the window is absorbed by nanosized particles (semiconductor quantum dots) dispersed in a glass window. The light is then re-emitted at the infrared wavelength invisible to the human eye, and wave-guided to a solar cell at the edge of the window. With this process, a virtually transparent window becomes an electrical generator, one that can power a room’s air conditioner on a hot day or a heater on a cold one.

A solar harvesting system uses small organic molecules to absorb specific nonvisible wavelengths of sunlight. They can be tuned to pick up just the ultraviolet and the near infrared wavelengths that then “glow” at another wavelength in the infrared. The "glowing" infrared light is guided to the edge where it is converted to electricity by thin strips of photovoltaic solar cells. Because the materials do not absorb or emit light in the visible spectrum, they look transparent to the human eye.

This technology opens a variety of markets to deploy solar energy in a non-intrusive way. It can be used on sky scrapers with lots of windows, or any kind of mobile device that demands high visual quality like a smart phone.

Another use for integrated photovoltaics is the agriculture industry by utilizing existing structures as a base for which luminescent solar concentrators can be installed. A waveguide coupled with photovoltaic cells utilizes fluorescent dyes that convert light unused by plants in greenhouses to wavelengths suitable for photosynthesis. The dye absorbs incident light and readmits it isotopically. Light that is not emitted in the escape cone is guided through total internal reflection to front-facing photovoltaic cells, thus providing the necessary light for plant growth and generating energy to power the greenhouse.

Researchers have demonstrated that sunlight, concentrated on nanoparticles, can produce steam with high energy efficiency. The “solar steam” device is intended to be used in areas of developing countries without electricity for applications such as purifying water or sterilizing medical instruments. The new solar steam method is so effective it can even produce steam from ice-cold water. This technology is meant for small conversions and cannot be used for a solar plant to drive steam engines

The efficiency of solar steam is owed to the light-capturing nanoparticles that convert sunlight into heat. The particles are very small—smaller than a wavelength of light—which means they have an extremely small surface area to dissipate heat. This intense heating generates steam locally—right at the surface of the particle.

When submerged in water and exposed to sunlight, the particles heat up so quickly that they instantly vaporize water and create steam. In ice water, the change to steam takes only 5 seconds. The nanoparticles convert 80% of the energy they absorb with carbon particles demonstrating greater efficiency than metal.

.png)

Lighting based on field-induced polymer electroluminescent technology gives off soft, white light in contrast to fluorescents and LEDs, which many people consider irritating. A nano-engineered polymer matrix is used to convert the charge into light. The technology allows the researchers to create an entirely new light bulb.

The new bulbs have the advantage of being shatterproof and twice as efficient than compact fluorescence light bulbs. Some researchers are developing high efficiency LED's using collections of nano-sized structures called plasmonic cavities.

The light is made of three layers of moldable white-emitting polymer blended with a small number of nanomaterials that glow when stimulated to create bright and perfectly white light, similar to the sunlight human eyes prefer. It can also be made in any color and any shape. This new light is at least twice as efficient as compact fluorescent (CFL) bulbs and on par with LEDs, but these bulbs won’t shatter and contaminate a home like CFLs or emit a bluish light like their LED counterparts.

Researchers have used sheets of nanotubes to build thermocells that generate electricity when the sides of the cell are at different temperatures. These nanotube sheets could be wrapped around hot pipes, such as the exhaust pipe of a car, to generate electricity from heat that is usually wasted.

Efficiently harvesting the thermal energy currently wasted in industrial plants or along pipelines could create local sources of clean energy that could be used to lower costs. The new thermocells use nanotube electrodes that provide a 3-times increase in energy conversion efficiency over conventional electrodes.

One of the thermocells looks just like the button cell batteries used in watches, calculators and other small electronics. The key difference is that these new thermocells can continuously generate electricity, instead of running down like a battery. Research can create other thermocells, including electrolyte-filled, textile-separated nanotube sheets that can be wrapped around pipes carrying hot waste streams of manufacturing or electrical power plants. The temperature difference between the pipe and its surroundings produces an electrochemical potential difference between the carbon nanotube sheets, which thermocells utilize to generate electricity.

.jpg)

Nanotube Thermocells Harvest Energy From Car Exhaust

One goal of nanotechnology is to improve photovoltaic solar electricity generation. The thermodynamic limit of 80% productivity is well beyond the capabilities of current photovoltaic technologies, whose performance now is only about 43%. A multidisciplinary, experimental and theoretical effort is now needed to make changes in the way solar cells are designed and manufactured. Nanotechnology provides a promising way to reach this goal with substantial increases in photovoltaic efficiency and cost reductions.

For additional information:

The content & opinions in this article are the author’s and do not necessarily represent the views of AltEnergyMag

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product