Study: Robots and AI Offer Significant Carbon Emissions Reductions by Operating Centuries Old Industries Better

By incorporating better use of data into some of the world's most carbon-dependent industries, the study found the equivalent of up to 18% of U.S. emissions could be eliminated by better operation.

ABB survey reveals unplanned downtime costs $103,000 per hour

It emphasizes the importance of effective maintenance strategies and service partnerships. 92% of respondents are interested in how outcome-based maintenance agreements can boost business success

What Role Does Polymeric Technology Play in Burgeoning Wind Industry?

Designed to safeguard the integrity of wind turbine blade leading edges for the long term, polymeric repair and protection technology plays a critical role in supporting this burgeoning industry.

Solar/Wireless Site Cameras Monitor Substations and Renewable Power Plants

CIPCO turned to Sensera Systems for a flexible camera solution that would meet the site security needs of the solar power plant project and the substation.

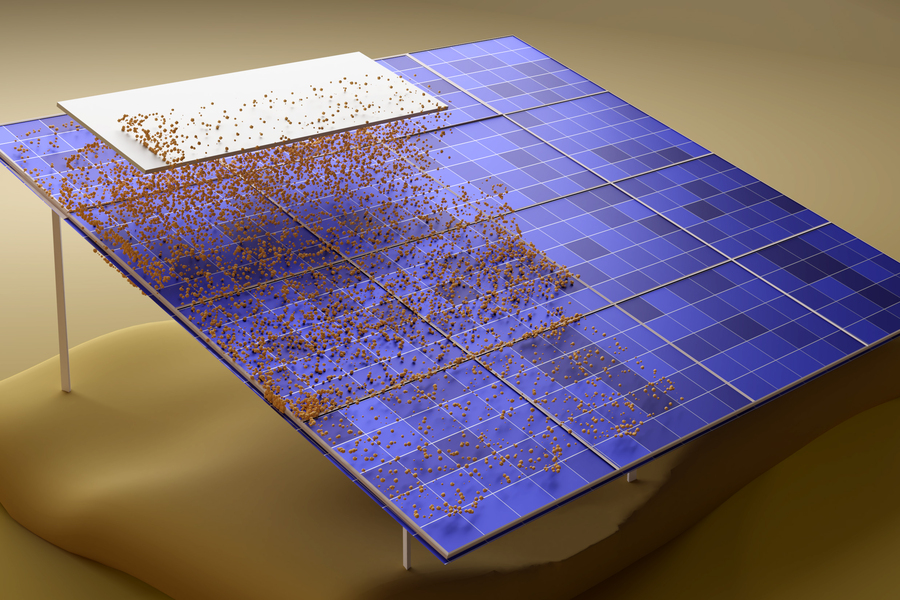

How to clean solar panels without water

A new cleaning method could remove dust on solar installations in water-limited regions, improving overall efficiency.

Solar Panel Cleaning and the Importance of Preventative Maintenance

There are several challenges, mainly due to the area where the cleaning is needed. For example, in Saudi Arabia, there are a lot of sandstorms. Therefore, the panels need to be dry cleaned almost every day.

Understanding Wind Turbine Fire Protection

A whopping 90% or more of wind turbine fires originate in the nacelle. The nacelle contains the gear box, the generator, the controller, the low- and high-speed shafts, and the brake-and it (the nacelle) sits atop the tower.

Preventative Maintenance for Renewable Energy

Engineers and scientists developed renewable energy systems to reduce society's adverse environmental impacts. We can align clean power devices with the systematic purpose by extending their life span and increasing their production.

5 Cases of Robotics in the Renewable Energy Industry

Robotics can decrease system installation and maintenance costs, increasing the general affordability of clean energy. They may additionally raise a system's efficiency levels and maintain adequate power supplies.

Automating Renewable Energy Maintenance

Companies can prevent issues by performing routine maintenance. These actions extend a renewable energy device's life and prevent its components from experiencing additional stress. Well-kept machinery can operate more efficiently than neglected solar or wind technology.

Increasing the Efficiency of Solar Power - Power Resistors Are a Key Solar Component

Solar PV systems aren't consistently efficient, with many hardly surpassing 20 per cent efficiency. Increasing the capability of solar PV systems is essential if we're to incorporate more solar energy into the grid.

Lead Acid Battery Install and Maintenance Tips

Steve Higgins, Technical Services Manager at Rolls Battery highlights some of the frequently asked questions when it comes to proper maintenance and service of lead acid batteries.

How to Protect Solar Panels from Environmental Damage

Solar PV systems spend all their time outside, so it's natural for them to encounter the occasional animal droppings or falling acorns. You may wonder how to keep them intact when more prominent issues like thunderstorms and hurricanes roll around, though.

Wind Turbines - Safe Operation After Expired Service Life

As wind farms age, an increasing number of turbine operators are confronted with crucial business decisions. Should the turbines be decommissioned? Will replacement bring a benefit?

Emerging Methods for Wind Turbine Operation and Maintenance

With the robust growth in the wind energy market, industry players have increased their focus on the optimization of O&M cost and aiming to sharpen their O&M strategies.

Records 1 to 15 of 35

Featured Product

Canadian Solar - HiKuBlack - Black Backsheet & Frame (Mono)

Aesthetic appearance for residential systems: With black backsheet & black frame, Power range 380 ~ 405 W, Low power loss in cell connection. Enhanced reliability: · Low temperature coefficient (Pmax): -0.34 % / °C, LID LeTID less than 2.0%, Lower hot spot temperature, Better shading tolerance.