A guide to maximizing production and profit with a DC converter.

Solar Plus Energy Storage

Chris Larsen | Dynapower Company, LLC

North America currently has over 20 GW of installed utility-scale PV generation with 2016 seeing the largest amount of PV installed to date with over 14 GW brought online. The majority of this installed utility-scale PV base could increase expand production hours and increase production with the addition of energy storage.

Here we will examine how a new cost-effective approach of coupling energy storage to existing PV arrays with a DC-to-DC converter can help maximize production and profi ts for existing utility-scale installations.

Here we will examine how a new cost-effective approach of coupling energy storage to existing PV arrays with a DC-to-DC converter can help maximize production and profi ts for existing utility-scale installations.

The addition of energy storage to an existing or new utility-scale PV installation allows system owners and operators the opportunity to capture additional revenues through:

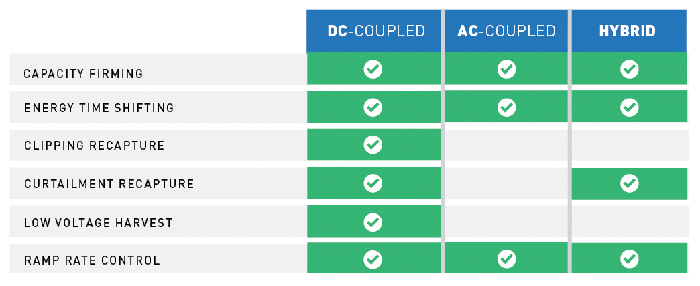

CAPACITY FIRMING

Turn Solar Energy into a Dispatch-able Asset

For certain time periods during the day the availability of storage gives the system operator the ability to bid fi rm capacity into merchant markets. That is storage makes PV generation a dispatch-able revenue generating asset. Depending on the available local power market, this may translate to higher kWh rates for fi rm capacity during dispatch-able periods.

ENERGY TIME SHIFTING

Utilize Generated PV Energy When Its Value is Highest

Energy Storage allows bulk energy shifting of solar generation to take advantage of higher PPA rates in peak periods, or to allow utilities to address daily peak demand that falls outside periods of solar generation.

.png)

CLIPPING RECAPTURE

Maximize Value of PV Generated Energy

Given common inverter loading ratios of 1.25:1 up to 1.5:1 on utility-scale PV (PVDC rating : PVAC rating), there is opportunity for the recapture of clipped energy through the addition of energy storage.

.png)

Using a simplified system for illustrative purposes, consider a 14MWDC PV array behind a total inverter capacity of 10MWAC. Depending on your location and type of racking, the total clipped energy can be over 1,000,000 kWh per year.

With storage attached to the array, the batteries can be charged with excess PV output when the PV inverter hits its peak rating and would otherwise begin clipping. This stored energy can then be fed into the grid at the appropriate time. Without energy storage these kWhs are lost and revenues stunted.

CURTAILMENT & OUTAGE RECAPTURE

Continuous uptime and revenue generation

When storage is on the DC bus behind the PV inverter, the energy storage system can operate and maintain the DC bus voltage when the PV inverter is off-line for scheduled or unplanned outages. When the PV inverter is offl ine the energy from the array can still fl ow to the batteries via the DC-DC converter ensuring energy can be harvested for later use.

.png)

The same uptime capabilities apply when a large utility scale array is curtailed by the ISO or utility. Curtailment is sometimes seen in areas of high solar penetration — such as California — when there is overall excess production on the grid. With a DC-coupled energy storage system, energy production can continue with energy being stored and available for discharge when curtailment.

LOW VOLTAGE HARVESTING

Make money on the edges

PV inverters typically require a minimum threshold DC bus voltage to operate. On a 1,500VDC nominal system, this ‘wake up’ voltage may be around 500VDC. As a result of this minimum voltage threshold, available generated energy in the morning and evening when voltage on the array is below the PV inverter ’wake up’ threshold is not captured. Adding energy storage through a DC-to-DC converter allows for the capture of this generated energy from the margins.

.png)

This phenomenon also takes place when there is cloud coverage. In both cases this lost energy could be captured by a DC-coupled energy storage system.

RAMP CONTROL RATE

Modulate Power for Continuous Grid Connection

Ramp rate control is often required by utilities and ISOs for PV and wind systems to mitigate the impact of a sudden injection of power onto the grid or a sudden loss of generation due to the intermittent nature of both generation sources.

A ramp rate of 1MW/minute, for example, has been required by HECO in Hawai’i to limit the speed with which a large array can come up to power or trail off in the event of cloud cover.

A storage system coupled with PV can monitor PV inverter output and inject or consume power to ensure the net output remains within the ramp requirements allowing for continuous energy injection into the grid. Additionally, with this ramp rate control benefi t, energy otherwise lost when a PV inverter would self-regulate during a ramp up (by manipulating the I-V curve to curtail power output) can now be stored for later use.

SYSTEM OPTIONS FOR COUPLING

The Case for Adding Energy Storage with a DC-to-DC Converter

There are three coupling system options for adding energy storage to new or existing solar installations — AC coupled solar plus storage, hybrid solar plus storage inverters and DC-to-DC Converter. Dynapower has extensive experience in developing, manufacturing and deploying inverters and converters for each of these options.

Here we outline the benefi ts of our latest solution — the DC-to-DC converter — which is particularly suited for adding energy storage to existing utility-scale solar arrays. The battery capacity (MWh) can be scaled according to the site use cases and project economics.

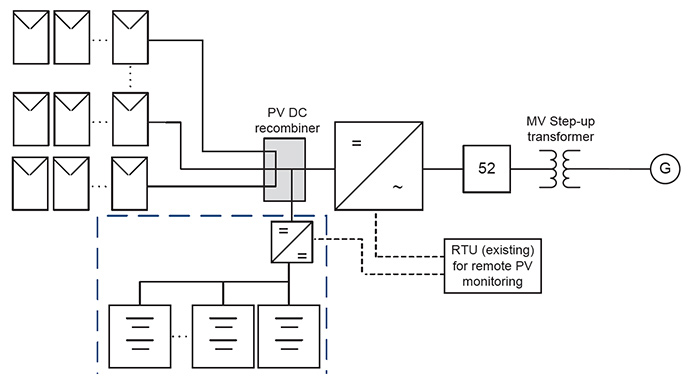

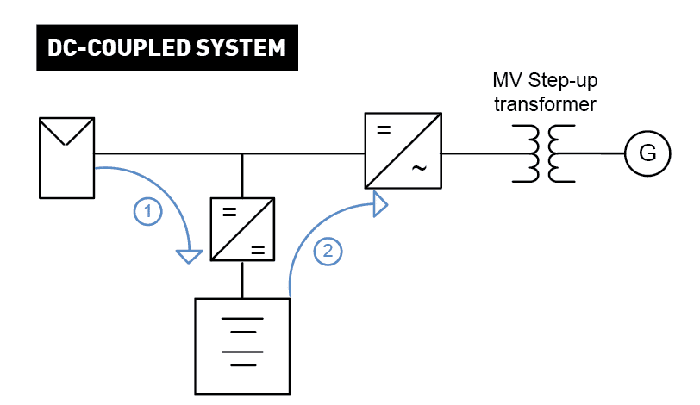

Figure 5 Illustrates the basic design of a DC-coupled system. In this set-up the storage ties in to the system behind the existing PV inverter and combines in parallel with existing PV strings at a recombiner. Depending on the size of the inverter and the use cases, designers can install multiple DC-DC converters in parallel on the DC PV bus.

FINANCIAL BENEFIT #1

Maximize all potential value streams

Of the previous outlined revenue streams available to PV arrays with energy storage, the DC-Coupled approach allows for revenues to be derived from all value streams — guaranteeing maximum value from an installed PV array. Not all revenue streams are available to AC-coupled solutions. By virtue of tying in on the AC side of the PV inverter, AC-coupled solutions by definition cannot recapture clipped DC energy for example.

FINANCIAL BENEFIT #2

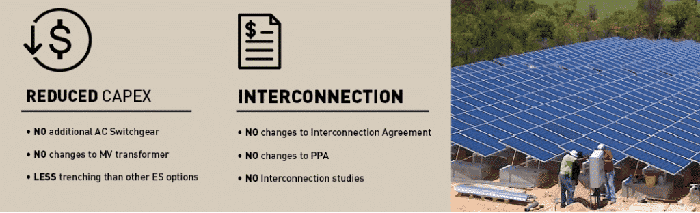

Lower Installation and Regulatory Costs

Secondly, by adding energy storage on the DC PV bus, costs associated with adding energy storage can be greatly reduced. This includes equipment and EPC costs for AC switchgear, MV transformers and associated trenching. Additionally, because none of the system’s AC characteristics change, there should be no need for a revised interconnection agreement or interconnection study. Likewise, depending on the off-taker, there may be no need to alter an existing PPA

FINANCIAL BENEFIT #3

Greatest Possible Efficiency

A chief concern with energy storage design for utility scale PV integration is optimizing for highest efficiency. As illustrated below, the efficiency achieved via a DC-coupled storage system is greater than for AC-coupled. This stems from the avoidance of funnelling power through two MV transformers in the charging process as is required by AC systems.

For the illustrative figures below we have even assumed a slight efficiency advantage in a DC-AC inverter over a DC-DC converter.

This figure illustrates the charge cycle (1) has single DC-DC conversion, while the discharge cycle (2) has DC-DC and DC-AC conversions and one transformer conversion. The net is 3 power electronic conversions and one transformer conversion in the round trip. Assuming the following effi ciencies, the net round trip effi ciency = 93.5% (98% DC-DC * 98% DC-DC * 98.4% AC-DC * 99% transformer.)

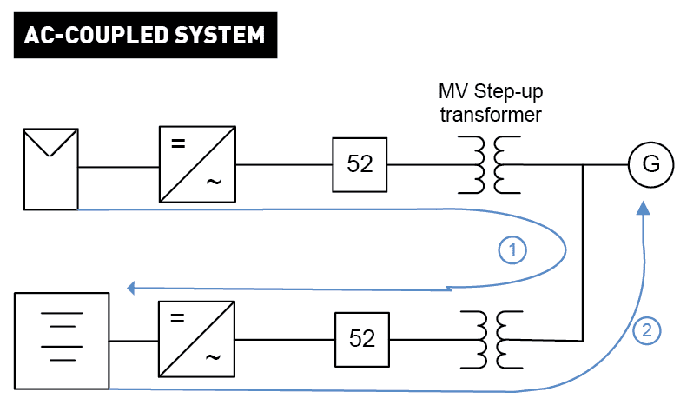

This figure illustrates an AC-coupled system where the charge cycle (1) has two DC-AC conversions and two transformer conversions and the discharge cycle (2) has a single DC-AC conversion and one transformer conversion. The net is 3 power electronic conversions and three transformer conversions in the round trip netting a total effi ciency of 92.4%. (98.4% inverter * 99% transformer * 99% transformer * 98.4% inverter * 98.4% inverter * 99% transformer)

FINANCIAL BENEFIT #4

Qualify for Tax Credits

The ability for a storage system to qualify for the federal PV investment tax credit (ITC) is based on the percentage of the battery charging energy that comes from the PV array. If charged energy from the array is less than 75% of the total for battery charging, then the battery system does not qualify for any ITC benefit. With a DC-coupled design, the storage system can only be charged from the PV array so there is zero risk of ITC claw back and tax credits are made available to the owner.

Furthermore, you eliminate the additional metering and controls needed with AC-coupled storage to verify that the batteries are charged from PV energy, further reducing CAPEX.

Conclusion

Dynapower recognizes that each PV installation has its own set of circumstances and considerations. As such we offer a full suite of options — AC-Coupled, Hybrid Solar Plus Storage and DC-Coupled — for coupling energy storage with utility scale PV installations. The DC-to-DC option can be an attractive option for coupling energy storage with existing PV. Its ease and reduced cost of installation as well as ability to bring online all additional value streams make it particularly attractive for the over 20 GW of installed utility-scale PV.

The content & opinions in this article are the author’s and do not necessarily represent the views of AltEnergyMag

Comments (0)

This post does not have any comments. Be the first to leave a comment below.