In the most-likely scenario, the experts predicted that hub height for newly installed onshore wind turbines will reach 130 meters in 2035, rather than the 115-meter forecast offered in a 2015 survey.

Experts Forecast the Wind Plant of the Future To Be Taller and More Economical

Research from | NREL

Anticipating key features of wind plants a decade or more ahead of their installation can inform today’s investment, research, and energy system planning decisions. Researchers Philipp Beiter and Eric Lantz from the National Renewable Energy Laboratory (NREL), together with collaborators from the Lawrence Berkeley National Laboratory and the U.S. Department of Energy, elicited opinions from more than 140 of the world’s leading experts about their expectations of future wind plant design in 2035.

In their new article, “Expert Perspectives on the Wind Plant of the Future,” which appears in the journal Wind Energy, the researchers find that experts expect the height of wind turbines to increase even greater than previously forecast, with plants located increasingly in less favorable wind and siting regions.

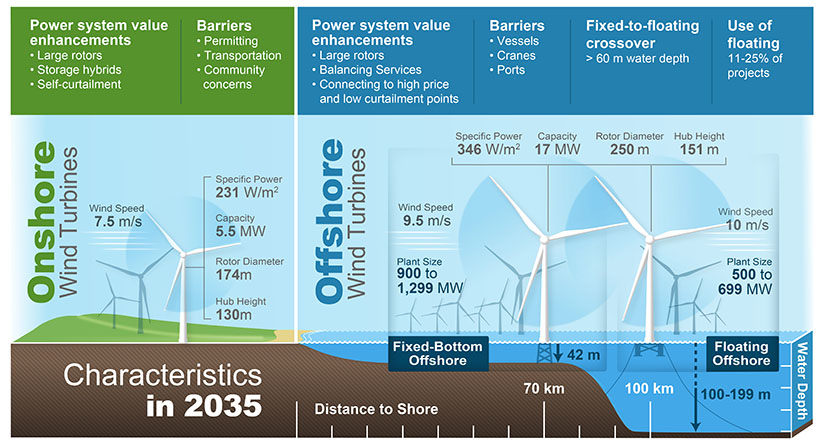

Taller turbines, and their accompanying larger rotor diameters, allow for the capture of more energy. In the most-likely scenario, the experts predicted that hub height for newly installed onshore wind turbines will reach 130 meters in 2035, rather than the 115-meter forecast offered in a 2015 survey. (Each survey asked experts to look 15 years into the future, so the 2015 data offers predictions for 2030).

Experts expect plant sizes of 1,100 megawatts (MW) for fixed-bottom and 600 MW for floating offshore wind. These and many other design choices discussed in the article can support levelized cost of energy reductions of 27% (onshore) and 17%–35% (floating and fixed-bottom offshore) by 2035 compared to today. New plant designs can also enhance wind energy’s grid service, for example, via project hybridization with batteries and hydrogen production.

“Our research provides a much-needed benchmark for representing future wind technologies in power sector models,” Beiter said. “By explaining the economics behind wind energy design choices, this article addresses a critical research gap.”

The authors identify economic mechanisms that drive these design changes, including economies of scale from larger turbines, larger plant size, and greater siting flexibility. In essence, these mechanisms drive design choices because the value from reduced costs or higher energy production exceed the incremental expense to obtain them.

“While well established in broader economic theory and often addressed individually, relatively few efforts have systematically investigated the exact mechanisms driving wind plant design,” Lantz said about the unique contribution of the study.

The comprehensive global expert survey was made possible through an international research partnership under the auspices of the International Energy Agency Wind Technology Collaboration Programme, whose mission is to advance wind energy research, development, and deployment in its member countries.

The Department of Energy’s Wind Energy Technologies Office funded the research.

NREL is the U.S. Department of Energy's primary national laboratory for renewable energy and energy efficiency research and development. NREL is operated for the Energy Department by the Alliance for Sustainable Energy LLC.

The content & opinions in this article are the author’s and do not necessarily represent the views of AltEnergyMag

Comments (0)

This post does not have any comments. Be the first to leave a comment below.