Lithos has now built a repeatable system through PICO to speed up prototyping, minimize losses, and ensure every change is intentional, traceable, and scalable.

Battery Manufacturer Cuts Scrap by 90% and Streamlines Prototyping

Battery Manufacturer Cuts Scrap by 90% and Streamlines Prototyping

Case Study from | Pico MES

In the fast-evolving world of battery manufacturing, prototyping isn’t just about innovation—it’s about efficiency, precision, and minimizing cost. At Lithos Energy, a California-based lithium-ion battery manufacturer, prototyping once came with high levels of scrap and slow iteration cycles. But thanks to PICO’s robust manufacturing process change control and traceability tools, the team has completely transformed how they manage early-stage production–saving time, reducing waste, and scaling smarter.

The Problem with Prototyping

At Lithos, the prototyping phase was necessary to optimize processes early on to prevent unnecessary costs and waste as production grows. This phase was largely owned by the design engineering team, who for a long time relied on paper travelers and siloed systems to document important assembly process data. While this team’s focus was on perfecting product features and performance, they lacked visibility into process efficiency and how the product would be built at scale.

The result? Slow iteration cycles and a significant amount of scrap.

“We had maybe 40 unplanned scrap units,” said Elliot Hu, Senior Manufacturing Engineer at Lithos. “And we couldn’t track the deviations or changes at the product level during prototyping.”

How to Reduce Manufacturing Scrap: Version Control & Traceability

To optimize the prototyping phase, Lithos turned to PICO’s change control and traceability features for help. This shift introduced consistent, end-to-end traceability and full version control–all in one place.

The results speak for themselves. With PICO, Lithos’ unplanned scrap dropped by 90%—from 40 units down to just one partial unit after only one iteration, and then to zero units after the second and third iterations.

Operators at Lithos Energy rely on PICO worker guidance to assemble lithium-ion battery packs for a variety of demanding applications.

Smart Manufacturing Relies On Automated Change Management

One of the standout benefits for Lithos is how PICO handles change control. When a process needs to be updated or revised, the new work instructions are instantaneously deployed to the shop floor.

“Everything is synchronized and controlled,” Elliot says. “We don’t have to waste time hunting down old instructions.”

The platform’s flexibility also empowers the team to make large-scale changes without being boxed into limited releases. Moving from version 1 to version 2 is a seamless, fast process—with previous data preserved and the new flow easily deployed.

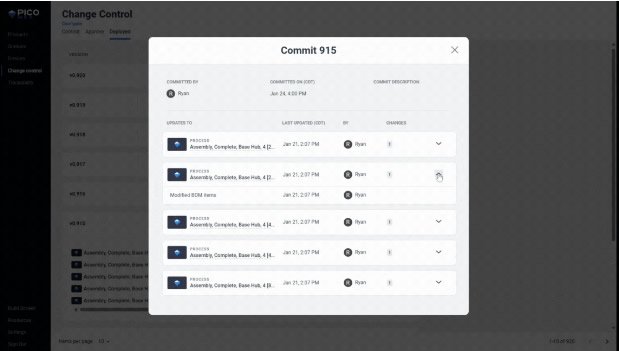

PICO makes change management easy through the Change Control feature, where all process updates–big or small–are logged, submitted for approval, and instantly deployed to the shop floor.

From Prototype to Production—Smarter and Faster

Lithos has now built a repeatable system through PICO to speed up prototyping, minimize losses, and ensure every change is intentional, traceable, and scalable. Whether it's small adjustments to their existing processes, or rolling out entirely new product lines, PICO enables their team to do it efficiently and with full traceability.

“If you have accurate data, you’re able to make educated, data-driven decisions constantly,” Angelo Menotti, Head of Quality at Lithos, notes. “That’s what allows us, as a small company, to do what big companies do.”

Automating data capture for traceability and leveraging change control in PICO has been a game-changer for small manufacturers like Lithos.

Key Takeaways for Battery Manufacturers

For any company wondering how to reduce scrap rate or streamline revision control for manufacturing, Lithos offers a powerful example:

- 90% reduction in unplanned scrap

- Faster prototyping cycles

- Real-time automated change control

- Scalable, flexible processes

“Thanks to PICO’s traceability features and its flexibility to get manufacturing instructions revised and deployed quickly and securely, we were able to cut down on our prototyping losses, reduce scrap, and speed up development,” Elliot concludes.

Next Steps:

🔹Sign up for free digital work instructions to begin error-proofing your assembly processes.

🔸Get a personalized demo to learn more about PICO's change management capabilities.

The content & opinions in this article are the author’s and do not necessarily represent the views of AltEnergyMag

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product