This article takes a look at what flexible solar actually is, along with its challenges, and the technical steps needed to make it a practical reality.

Printed, Placed, Powered: Can Robotics Close the Gap in Flexible Solar Manufacturing?

Article from | Ossila

Flexible photovoltaics sound like a thing of the future, and they promise to turn almost any surface into a source of energy. But while the technology is exciting, it still faces major challenges, particularly in the manufacturing processes. Producing ultra-thin, multi-layered solar cells at scale requires a level of precision that traditional methods just can’t yet achieve.

Enter robotics, the missing link that could be combined with roll-to-roll processes and real-time quality control to create a viable solution to these bottlenecks. This article takes a look at what flexible solar actually is, along with its challenges, and the technical steps needed to make it a practical reality.

What are Flexible Solar Cells and Why Do They Matter?

When we hear about new developments in the solar industry, the spotlight is usually on improvements to efficiency and finding new materials or methods that can generate more usable energy per square metre. But flexible solar cells represent a different kind of innovation. Rather than prioritising maximising energy efficiency, their focus is on creating solar panels that are practical and versatile, even if it means sacrificing some performance.

As the name suggests, flexible solar panels are not the rigid silicon rectangles that we are used to seeing on rooftops. Instead, they resemble thin, lightweight sheets - you can almost imagine them as solar-powered paper. This makes them highly deformable and suitable for surfaces that traditional solar panels simply can’t work with.

The underlying technologies behind flexible solar cells is still in its early stages, but several types of solar cells are being explored. Most commonly, to create flexible solar panels we’re seeing variation of thin film photovoltaics, organic solar cells, perovskites, and printed solar inks being deposited on flexible substrates such as plastics or metal foil.

The potential applications of flexible solar cells are vast. Imagine solar-integrated wearables, solar-powered vehicles, tents, glass facades, or even building materials that can passively generate power. With flexible solar, virtually any surface has the potential to become a solar-based energy source.

As of now, the technology still faces hurdles. Unlike traditional silicon solar panels, the materials used in flexible solar cells are still lacking the long-term stability and durability that is required for widespread deployment. Understandably, this is a big concern when you consider the inherent exposure to bending and mechanical stress that rigid solar panels avoid. Additionally, the manufacturing process is highly precise and expensive, requiring exact deposition and layering techniques that are difficult to scale in an affordable way.

Why Manufacturing is the Bottleneck

No matter how far research progresses in improving the performance and reliability of flexible solar cells, one major issue remains: manufacturing at scale. This is arguably the biggest barrier to turning flexible solar into a technology that is commercially viable.

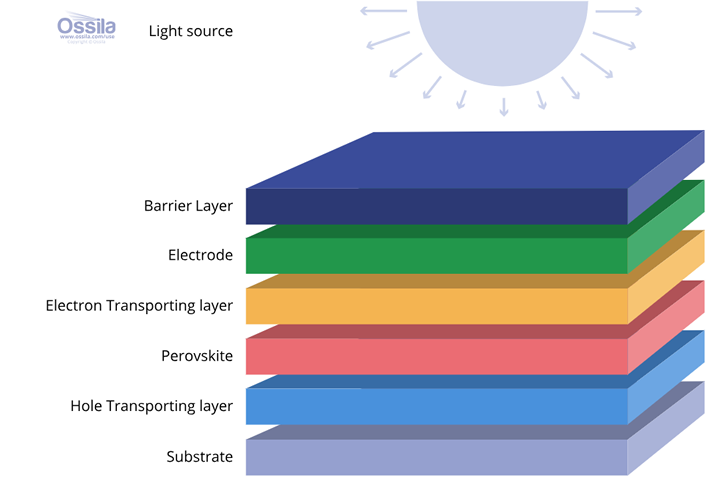

As previously mentioned, producing flexible solar cells involves multiple ultra-thin layers, including electrodes, absorber materials, and transport layers. Each of these must be deposited with micron-level precision, and are often fabricated in controlled environments. That level of control is difficult enough in the lab, nevermind on a high throughput production line. To put it simply, humans are not precise enough to achieve this, especially when we factor speed and scale into the problem.

Where this starts to become a real challenge is when we consider that existing solar factories just aren’t designed for this kind of manufacturing. Our current solar infrastructure is optimised for rigid, silicon panels which are the current industry standard. Flexible solar, particularly thin-film technology, requires completely different processes and tools. As such, they require new, specialised manufacturing plants to be built but justifying this is difficult when the market demand still very much revolves around silicon-based solar.

Without automation, manufacturers face low throughput, inconsistent product quality, and no real path to scalability. That’s where roll-to-roll (R2R) manufacturing comes into a play. Here. flexible substrates are continuously fed through a series of deposition and layering stages, increasing production speed. But to meet the exacting demands of flexible solar cell fabrication, it needs to be paired with robotics, giving us precise control over tension, pressure, alignment, and registration throughout the process.

Where Robotics Fits Into This

If flexible solar is ever going to scale, robotics will need to take a central role both in manufacturing processes and eventual deployment.

Flexible solar production requires a level of accuracy and repeatability that humans just can’t achieve alone. However, the combination of robotics with R2R manufacturing could be a solution:

- Robotic substrate handling: Robots can manage ultra-thin films that are fragile whilst remaining delicate and providing the constant tension that is needed for continuous processing. This helps to avoid tears or misalignment, issues that can slow down the manufacturing process otherwise.

- Automated coating heads: Using robotics, it is possible to create dispensing systems that can deposit exact material volumes for each layer, helping to reduce material waste and defects.

- Quality control: Computer-vision quality control can be implemented via real-time defect detection paired with self-correcting robotic arms. In doing so, processes can be adjusted on the fly, so the quality of solar cells produced stays consistent without having to stop production altogether.

- Module assembly: Robotics has potential uses other than the printing processes, and can also be used to laminate and interconnect individual layers into finished modules. This means that the entire manufacturing process, from material to solar cell, can be completed with little human intervention.

Beyond manufacturing, robotics could be used in the installation of solar panels, particularly in dangerous or hard-to-reach areas. Though flexible solar panels have the potential to be used almost anywhere, getting them into position isn’t always a straightforward process. As such, drones and climbing robots could be used to install these solar panels.

What needs to happen next to make this a reality?

For both flexible solar and the robotics supporting it to move forward from just being a prototype, there are still some challenges to overcome.

Even with improved automation, one of the biggest challenges is in the materials themselves. Leading candidates for flexible solar cells like perovskites show a lot of promise but suffer from instability and rapid degradation. This is particularly a problem when exposed to moisture, oxygen, and UV light - all things that a solar panel should be able to resist. Improving the durability and lifespan of these materials is essential if they’re going to be used in real-world applications.

The next challenge comes down to the manufacturing processes. It’s easy to say that robotics and R2R processes could be used together, but actually implementing them in a way that fits industry demands will take some work. Current R2R systems work, but not at the scale or yield that is needed for mass production. To make flexible solar cost-competitive, manufacturers need to create systems that have higher throughput and automated quality control built into every stage.

On the economics side, the overall associated costs need to come down significantly. This means optimising robotics systems for affordability and streamlining supply chains for flexible PV materials in particular. There’s also the bigger question of whether we should stick with a few giant solar factories or decentralise manufacturing to smaller, modular ‘microfactories’. Decentralising could bring flexible solar production to the places that it’s needed most, therefore reducing shipping costs and helping to power off-grid regions. By pairing compact R2R lines with robotics, this vision could be a reality.

Conclusions

In short, a combination of better materials and smarter manufacturing processes are needed to make flexible solar panels a reality. Robotics will play an important role in this, but it’s only part of a bigger shift in how we produce and deploy the next generation of renewable energy.

Backed by decades of experience, Ossila paves the way to scientific discovery in research institutions across the globe. We offer high-performance research tools, high-quality materials, and dependable laboratory supplies at accessible prices, equipping you with everything you need to make high-impact discoveries.

The content & opinions in this article are the author’s and do not necessarily represent the views of AltEnergyMag

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product