UK based Storelectric, discusses the current state of the clean energy transition worldwide, the need for long-duration energy storage, the place for hydrogen in national grids, and a way to eliminate the renewable energy intermittency issue.

The Long-term Energy Storage Conundrum and Its Impact on the Clean Energy Transition

The Long-term Energy Storage Conundrum and Its Impact on the Clean Energy Transition

Q&A with Mark Howitt, CTO | Storelectric

A key factor holding back the transition from CO2 intensive fossil fuel based power generation to clean (green) energy-based sustainable production is that of how to store energy that is essentially intermittently produced.

In an exclusive interview with BXD, Mark Howitt, CTO of Manchester, UK based Storelectric, discusses the current state of the clean energy transition worldwide, the need for long-duration energy storage, the place for hydrogen in national grids, and a way to eliminate the renewable energy intermittency issue, reduce energy wastage and increase efficiency.

BXD: How do you feel the energy transition in electricity systems is progressing around the world?

MH: In the UK, Europe and North America, there's huge growth in renewable and clean energy, and short-duration storage. But long-duration storage just hasn't been built, which is what's increasing the cost of electricity exponentially. The Putin premium is merely the icing on the cake.

Despite their fossil fuel investments, the Chinese are also investing heavily in renewables, and in Compressed Air Energy Storage, of which they have one built recently and eight in the pipeline, despite their higher cost and lower efficiency. So their prices aren't rocketing in the same way.

Most of the rest of the world has to catch up, though India's working on developing renewable electricity generation fast.

BXD: What needs to be done to get enough long-duration storage built?

MH: First of a kind plants need to be supported and encouraged in all technologies that offer a potential solution. The support to them could be limited so only the most cost-effective would be built. Then they need contracts that suit them. All such technologies have long construction lead times – the biggest issue being the time that grids take to make the connections – and are naturally inertial, delivering a range of services to the grid that can't be delivered separately, and so should be contracted together.

BXD: Please explain the implications of inertia in electricity production.

MH: When inertial generation and storage deliver energy, including balancing services, they have parts that spin at a calculated frequency. Therefore they concurrently deliver inertia, other stability services, reactive power and load, voltage and frequency control, and restoration services completely naturally. They can't deliver the energy without delivering all of these.

So where these services are contracted separately, the contracts for inertial generation and storage must be linked. However many say that this issue will be resolved with hydrogen-powered generation.

BXD: What do you think about the future for hydrogen in electricity generation?

MH: If seasonal storage is needed – and the jury's still out on that – then hydrogen-powered generation will be essential. But other than that, the cycle of renewable generation to electrolysis, to hydrogen-powered generation, to electricity on the grid is, at best, mid-40s percent efficient, currently mid-20s percent, and realistically achievable at mid-30s percent.

And the combined electrolysis storage and generation equipment required for this is costlier than our 68-70 percent efficient 'Green CAES' technology, which I therefore believe is better for those applications.

Hydrogen has various applications for which it's best.

BXD: What are those applications?

MH: Hydrogen is perfect for the gas grid: up to 10-15 percent mix with natural gas can be achieved with minimal network modifications and upgrades. Beyond that, it's inappropriate until you hit 100 percent. That's because a mix is only useful where it's being burned. But the applications for which hydrogen is best suited require 100 percent purity – applications such as fuel cells, transportation, fuel and chemical synthesis, iron smelting, steel production, and so on.

BXD: So how can the grids make the jump from 15 percent hydrogen to 100 percent?

MH: By creating hydrogen-industry hubs, in which hydrogen is both produced and used in bulk. This incidentally will also minimise costs and the need for hydrogen storage.

Within the hydrogen hub it's piped at 100 percent concentration, isolated from the general gas grid which is limited to 10-15 percent. These hubs can then grow to neighbouring areas, eventually merging to include the entire grid.

Hydrogen producers can use the grid to meet swing demand, taking all surplus output until it can be piped to users of pure hydrogen. They'd switch to doing so, allowing other producers to take their place on the grid. This will greatly accelerate the hydrogen transition.

BXD: The existing gas grid has lots of storage. Will the hydrogen economy also need it? And if so, how?

MH: Yes, it will need as much storage per unit of demand as the gas grid, though I believe that the hydrogen economy will require only about half the demand. That's because I believe that the electric economy will grow and partially supplant it, such as with heat pumps.

But that still needs a fantastic amount of bulk storage, and even more so as the energy density of hydrogen is about two-thirds that of methane. And the only way currently available to store hydrogen in such massive quantities is in salt caverns, just like those in which we'll, at least initially, be storing our air for the Compressed Air Energy Storage (CAES).

Therefore the hydrogen can be stored in adjacent caverns, making integrated projects even more efficient and cost-effective.

BXD: And will the hydrogen economy be powered by renewables?

MH: Yes, but not in the way that many think. Lots of people suggest using electrolysis to take out the intermittency of renewable generation. But in general, electrolysis - and most hydrogen-using technologies - dislike intermittency, which reduces their efficiency and plant life while multiplying the investment needed many-fold.

For example, assuming no hit to efficiency from intermittency, you need 2.5 times as many electrolysers if powered by 40 percent load-factor offshore wind than if powered by baseload electricity; three times more for 33 percent load-factor onshore wind; and six times more for 17 percent load factor solar.

So using our 'Green CAES' to remove the intermittency before it hits the electrolysers and other plants is extremely cost-effective as well as enhancing efficiency and plant life. And the more integrated the local hydrogen-related industry is, the more efficient and cost-effective the whole lot will be.

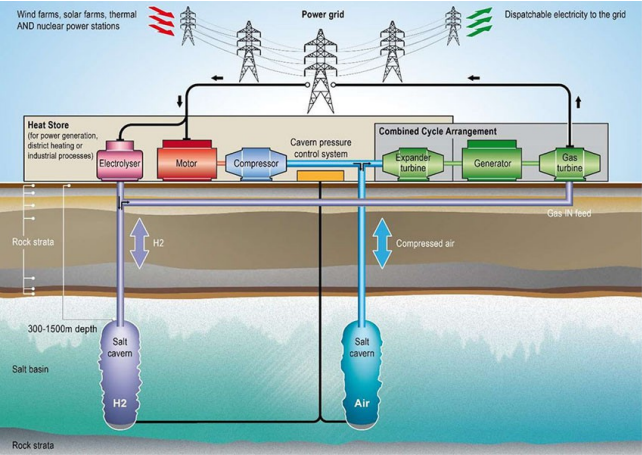

Hydrogen CAESTM as part of an integrated energy system. © Storelectric Limited

In addition to their activities in several parts of the world, Storelectric recently announced that it is currently in talks with a number of potential investors and partners in the Middle East and North Africa – a region where ambitious strategies and investment in renewable energy is well under way, driven by the need to meet growing energy demand, assist economic growth, maximise socioeconomic benefits, and meet decarbonisation objectives.

The region not only has the advantage of suitable geology, but is also perfect for enabling their almost unlimited solar resource to power the electricity system and hydrogen economy, including export of green products like ammonia, methanol, iron and steel; also for powering fundamental infrastructure like desalination and water treatment.

The content & opinions in this article are the author’s and do not necessarily represent the views of AltEnergyMag

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product