Next generation waste management may be significantly improved by using different technology to better manage solid wastes.

There's Gold In Them Thar Waste Hills

C. G. (Chuck) Steiner | WaterSmart Environmental, Inc.

| Next generation waste management may be significantly improved by using different technology to better manage solid wastes. |

|

|

by C. G. (Chuck) Steiner President and CEO WaterSmart Environmental, Inc. |

No--not real gold, and not fool's gold either--but rather a whole lot of potential value. Them Thar Waste Hills consist of large piles of municipal solid wastes; culm, gob, and waste coal piles; phosphogypsum stacks; and overburden piles from oil sands strip and pit mining. The waste hills range in size from a small to large. The very small hill, for example, of municipal solid wastes (MSW) at beautiful Key West, Florida is also the highest point in the city unless the two latest hurricanes have dispersed the wastes to the adjacent ocean. Other MSW hills are many times larger. The potential value associated with all such waste hills depends entirely on how they are managed.

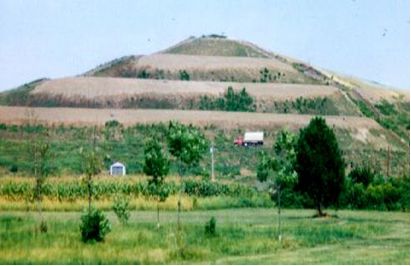

Typical Active Landfill Nearing Its Fill Capacity

Very Top Of Above Landfill Showing Waste Spreading And Compaction Activities

Typical Hurricane Katrina Waste Pile Traditional MSW management for the last 75 years called for burying the wastes and covering them with dirt until the landfill site could hold no more, eventually forming a large hill at full capacity. Some 25 years ago enterprising waste-to-energy companies started a new management approach by generating electricity from MSW. This was accomplished by burning the MSW to create heat. The heat was used to produce high pressure steam. The steam in turn powered a steam turbine electric generator. The resulting waste-to-energy plants are commonly referred to as mass burn MSW waste-to-energy facilities. During the last 15 years marketplace efforts have been made to prevent the continuing discharge of methane gas from landfills. Methane gas is the most detrimental greenhouse gas, perhaps 20 times as harmful to the environment as carbon dioxide gas. By burning the methane in a gas powered electric generator the gas is converted into carbon dioxide gas as electricity is produced.

Next generation waste management may be significantly improved by using different technology to better manage solid wastes. The next generation technology calls for the anaerobic digestion of MSW that produces biogas in the same manner that landfills produce biogas. Municipalities are quite familiar with anaerobic digestion technology since some 10,000 already own and operate anaerobic digesters and have been doing so for the last 75 years. The biogas can be beneficially used by generating electricity in the same manner that landfills are converting methane gas to electricity. This method of waste management, however, is easily capable of producing over twice as much electricity as mass burn MSW facilities are able to accomplish by using improved anaerobic digestion technology. There are now over 100 MSW-to-energy plants in operation in 31 states throughout the United States. These plants incinerate about 15% of the total trash generated or about 105,000 tons per day. On a consolidated basis, these plants generate approximately 2,769 megawatts of electricity. The investment in capital facilities totals more than $10 billion. These MSW-to-energy (also called biomass-to-energy) plants represent extremely inefficient conversion of Btus (British Thermal Units) to electricity. The total electricity generated can be converted into equivalent Btus by multiplying the total kWh by 3,414. 2,769MW x 1000 kW/MW x 24h x 3,414Btu/kWh = 226,880,784,000 Btus. The total 105,000 tons of trash per day is equivalent to 105,000 x 2,000 lbs/ton = 210,000,000 lbs/day. Dividing the total Btus/day by the lbs of trash/day results in an average Btu/lb of trash or 226,880,784,000 divided by 210,000,000 = 1,080 Btu/lb average. Since MSW has a rather well known Btu value of about 4,750 Btu/lb, the total system conversion efficiency of existing MSW-to-energy is 1,080 divided by 4,750 x 100% = 22.7%. According to the US Department of Energy, biomass-to-electricity through pyrolysis technology (same as mass burn MSW facilities) exhibits an efficiency of approximately 20%. These dismal efficiencies of dry processing are, for the most part, attributable to the inherent high moisture content of biomass. Anaerobic digestion technology is a wet rather than dry process. Moisture is a process requirement rather than an operational detriment. The ability of anaerobic digestion to convert Btus into electricity may be theoretically determined as follows: MSW has an average organic content of about 70%. 70% of 210,000,000 lbs/day = 147,000,000 lbs/day. Of this amount, approximately 75% are volatile solids or 0.75 x 147,000,000 = 110,250,000 lbs/day. The new and improved OAT™ process of anaerobic digestion produces about 12 cubic feet of methane/lb volatile solids. The total methane produced at 99% volatile solids to methane efficiency is found by 110,250,000 x 12 x 0.99 = 1,309,770,000 cubic feet/day. The next step is to convert the methane into electricity. The hourly methane production is found by dividing the daily production by 24 or 1,323,000,000/24 = 54,573,750 CFH (cubic feet per hour). This figure divided by about 12 equals the kW sized gas generator that would convert the total methane into electricity or 54,573,750/12 = 4,548,000 kW. kW/1000 = MW or 4,548,000/1000 = 4,548 MW or 1.64 times as much as existing MSW-to-energy mass burn technology. This establishes a greatly improved biomass-to-electricity efficiency to 36%. By adding combined cycle generation, the efficiency increases above 50% or more than twice as much electricity than existing state-of-the-art mass burn MSW facilities. Combined cycle refers to the practice of using the waste heat from a power generation device to produce steam. The steam, in turn, is beneficially used to produce additional electricity through the use of a steam turbine generator. Steam generation is the only method of making electricity in existing mass burn MSW facilities. The splendid improvements in generation efficiency can be accomplished by applying common scientific principles to existing and fully established well known technologies. New technology doesn't have to be created. Existing technologies must be used in a different manner than before. It's that simple. The use of new and improved anaerobic digestion technology to manage MSW is therefore far more effective than existing waste management practices in terms of total marketplace value produced. A bit of gold from a pile of trash one might conclude. Coal provides nearly 50% of the electrical generating fuel in the United States and similar percentages apply around the world. Coal is more abundant than oil, if fact, coal reserves are far more abundant than oil reserves. There is enough coal on the earth to supply all the current energy requirements of the entire planet for hundreds of years. Coal is many times more abundant than the reserves of all other fossil fuels combined. In the normal mining of coal its overburden must first be removed. The resulting piles of overburden materials become waste coal. They are called "culm" piles in the eastern Pennsylvania anthracite coal region and "gob" or "boney" piles in the bitiminous coal mining regions of western Pennsylvania, West Virginia, and elsewhere.

Nemacolin Gob Pile in Greene County, Pennsylvania

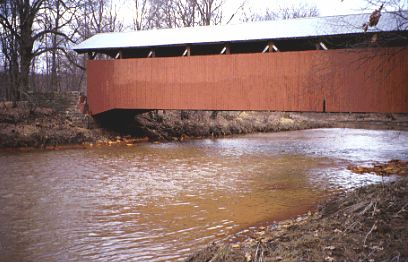

The effects of Acid Mine Drainage (AMD) on Shamokin Creek approximately 13 miles downstream of the last mine discharge. This location is 3 miles from its confluence with the Susquehanna River. The Susquehanna River is the nation's sixteenth largest river and is the largest river lying entirely in the United States that flows into the Atlantic Ocean. The Susquehanna and its tributaries drain 27,510 square miles spread over parts of the states of Maryland, New York, and Pennsylvania. The river meanders 444 miles from its origin at Otsego Lake near Cooperstown, New York until it empties into the Chesapeake Bay at Havre de Grace, Maryland. The Susquehanna contributes one-half of the freshwater flow to the Bay. Acid mine drainage occurs in several tributaries to the Susquehanna. Acid mine waste pollution is caused by the physical and chemical weathering of a very common mineral. The main culprit seems to be iron pyrite, a mineral as "fool's gold". The level of acidity and the concentration of heavy metal pollutants in the mine drainage can be directly correlated to the amount of pyrite in the area around the mine. Physical weathering of the pyrite is essential to reduce the grain size of the mineral. The early miners inadvertently accelerated this process by grinding up the ore and dumping the overburden in the mine tailings piles. Raw coal may be sold as mined or may be processed in a beneficiation/washing plant to remove noncombustible materials (up to 45% reduction in ash content) and inorganic sulfur (up to 25% reduction). Coal beneficiation is achieved with wet physical processes such as gravity separation and dissolved air flotation. Beneficiation produces two waste streams: fine materials that are discharged as a slurry to a tailings impoundment, and coarse materials (typically greater than 0.5 millimeters in size).

Typical Tailings Ponds Whether gob/culm piles or tailings ponds the chemistry of acid mine drainage remains the same namely the chemical oxidation of pyrite described in the following reactions: 4FeS2(s) + 14O2(g) + 4H2O(l) ---> 4Fe2+(aq) + 8SO42-(aq) + 8H+(aq) (1) Iron II ions and acidic hydrogen ions are released into the waters that runoff from the mine drainage tunnels or tailings piles. Iron II ions are oxidized to form iron III ions as shown in the following reaction: 4Fe2+(aq) + O2(g) + 4H+(aq) ---> 4Fe3+(aq) + 2H2O(l) (2) The iron III ions now hydrolyze in water to form iron III hydroxide. This process releases even more hydrogen ions into the aquatic environment and continues to reduce the pH. The iron III hydroxide formed in this reaction is called "yellow boy", a yellowish-orange precipitate that turns the acidic runoff in the streams to an orange or red color and covers the stream bed with a slimy coating. Aquatic life that dwells on the bottom channel of the stream is soon killed off. Equation 3 describes this reaction: 4Fe3+(aq) + 12 H2O(l) ---> 4Fe(OH)3(s) + 12H+(aq) (3) If we were to look at the net effect of equations 1-3, we would find that the pyrite is oxidized releasing acidic hydrogen ions into the water and coating the stream bed with "yellow boy". The sum of equations 1-3 is shown in the following reaction: 4FeS2(s) + 15O2(g) + 14H2O(l) ---> 4Fe(OH)3(s) + 8SO42-(aq) + 16H+(aq) (4) Complex systems in nature such as mine tailings piles and mine draining tunnels cannot be described by just a few equations. Other chemical reactions are occurring as shown in equation 5. In addition, sulfides of copper, zinc, cadmium, lead and arsenic will undergo similar geochemical reactions resulting in the contribution of toxic metal ions into mine waste water. Other factors such as the presence of acidic tolerant bacteria (ex. Thiobacillus ferroxidans) can also speed up the process of sulfide oxidation. FeS2(aq) + 14Fe2+(aq) + 8H2O(l) ---> 15Fe3+(aq) + 2SO42-(aq) + 16H+(aq) (5) There are thousands of gob and culm piles, tailings ponds, and associated discharge streams that continue to inflict environmental damage. Remediation efforts to date have consisted of revegetation. Revegetation does little to stop acid mine drainage damage as every rainfall event continues to add to the acid mine drainage volume through waste coal percolation.

Revegetation Project Underway Nationally, waste coal has an average of 60% of the BTU value (British Thermal Units, a unit of energy) of normal coals. It can take up to twice as much waste coal to produce the same amount of electricity. This means that, in most places, waste coal burners can only be economically built where huge volumes of waste coal exist. It would cost too much to truck far-away low-BTU fuel to a centralized burner. Consequently, even if waste coal burning were a clean solution, it wouldn't deal with the problem of more isolated waste coal piles. Burning waste coal doesn't make the waste go away. If 100 tons of waste coal are burned, 85 tons will remain as waste coal ash. Since far more mercury and other toxic contaminants enter a waste coal burner to produce a given amount of electricity, these high levels of toxic contaminants have to come out somewhere. Toxic metals cannot be destroyed by burning them. To the extent that they are captured in pollution controls (protecting the air), they are then concentrated in the highly toxic ash that ultimately threatens the groundwater wherever this ash is dumped. Waste coal burners have cleaner air emissions than antiquated coal plants due to their better pollution controls, but this only means that the ash is far more toxic, since the highly toxic particulates captured in pollution control equipment end up in the ash. The industry claims that 99.8% of the mercury in the fuel is captured and ends up in their ash. Waste coal ash is dumped in communities not far from the waste coal burners, threatening the groundwater with leaching lead, mercury and other poisons. Power plant waste is allowed to be dumped without the basic protections (landfill liners) that are required for dumping household trash. When burning any solid fuel, the resulting ash has a higher surface area than the raw, unburned material. The dangers of toxic leaching from ash can be expected to be greater than from the unburned waste coal. The industry claims that by injecting limestone into the ash, the ash becomes impervious to leaching. However, this has not been proven and it seems likely that the alkaline affects of the lime would afford only temporary protection, especially since the region where most of the waste coal burners are (Pennsylvania, West Virginia) suffers from the nation's worst acid rain that would tend to deplete the effects of lime addition. The waste coal burning industry's own data shows that waste coal ash does in fact leach metals into groundwater, despite their public assertions to the contrary. Ashes at 2 of 12 facilities studied in Pennsylvania were shown to contain levels of arsenic higher than the maximum allowable concentration set forth for land application of sewage sludge. Of 221 samples of leachate from waste coal ash at the ash dumps, lead contamination in 23 samples (10.4%) exceeded a level 10 times higher than EPA's maximum contaminant level (MCL) for drinking water. Six samples exceeded this "10 times the drinking water standard" level for cadmium, as did single samples for chromium and selenium. In short, the chemistry of acid mine drainage from gob/culm piles and tailings ponds remains the same for waste coal ash.

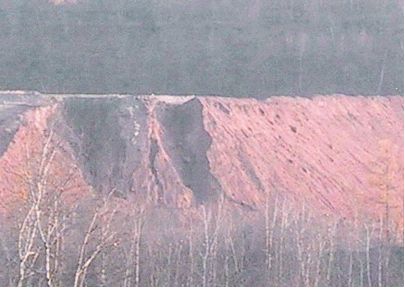

Waste Coal Ash Pile in Schuylkill

County, Pennsylvania For the last 100 years the combustion of coal for electricity and steel making has resulted in large financial rewards for all of its private and governmental stakeholders. One cannot hope for or expect the waste piles to go away very fast notwithstanding the continuing and increasing environmental damage. A single solution for all the waste piles consists of their encapsulation in concrete wall panels for use in the building industry. Concrete encapsulation permanently captures every one of the waste piles nasty constituents forever preventing their release and damage to the environment. This result could be realized if the owners of, or those otherwise responsible for, these clearly hazardous waste piles were persuaded to dispose of the waste piles in a timely manner consistent. Over the years the EPA has consistently exempted all piles associated with the combustion of coal by excluding them from hazardous waste regulations. A concrete wall panel manufacturer might be willing to accept these wastes as though they were, say, common ordinary non-hazardous municipal solid wastes by paying a quite reasonable tipping fee. Concrete manufacturing requires the use of aggregates. Some CCBs are already being used in manufacturing concrete. There is every reason to believe that gob and culm piles can also be used in concrete manufacturing. One concrete wall panel company with visions of value in waste coal piles is now proposing this permanent solution. Another bit of gold from a pile of waste coal one might conclude. Phosphogypsum (PG) is a radioactive byproduct of the fertilizer industry. To make 1 pound of commercial fertilizer, the phosphate industry creates 5 pounds of contaminated phosphogypsum slurry (calcium sulfate). This slurry is piped from the processing facilities up into the acidic wastewater ponds that sit atop the mountainous waste piles known as phosphogypsum stacks.

Typical Phosphogypsum Stack

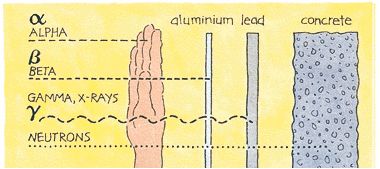

Typical Phosphogypsum Stack According to the EPA, 32 million tons of new gypsum waste is created each year by the phosphate industry in Central Florida alone. Central Florida is the heart of the US phosphate industry. The EPA estimates that the current stockpile of waste in Central Florida's gypsum stacks has reached "nearly 1 billion metric tons." The average phosphogypsum stack takes up about 135 acres of surface area - equal to about 100 football fields - and can go as high as 200 feet. While radioactivities naturally occurs in the phosphate ore, their concentrations in the phosphogypsum waste stacks, after the extraction of soluble phosphate, are up to 60 times greater than the phosphate fertilizer produced. The fertilizer goes to the marketplace. The radioactive phosphogypsum stacks stay behind in the form of massive phosphogypsum stacks.. The radioactivity in phosphogypsum stacks comes from Uranium (U) and Thorium (Th) both of which are always present where phosphates are mined. The radiation energy (MeV) consists of Alpha (α) decay particles, Beta (β) decay particles, and Gamma (γ) rays. The penetrating power of α, β, and γ radiation is shown in the following illustration:

A single sheet of paper also stops weak α radiation. Very strong neutron radiation is associated with nuclear power plants that are designed to contain the nuclear radiation within concrete vessels. Uranium (U-238) is a radioactive element that occurs naturally in low concentrations. It degrades to U-235 by emitting an α particle. Continuing degradation consists of Radium (Ra)-226, then Radon gas (Rn)-222, and lastly stable non-radioactive Lead (Pb)-206. Thorium (Th)-232 degrades to Ra, then Rn, and lastly to non-radioactive Pb-208. Radon is a gas that represents the most serious degradation product from a human health standpoint. Way back in 1989, the USEPA issued the National Emission Standards for Hazardous Air Pollutants. The standard required that all PG be stored in stacks. It did not permit any other uses, such as in agriculture or indoor research and development. In 1992, in response to several petitions, EPA revised the standard to permit use but a safe limit was set at 10 pCi/g and the international limit prescribed by euratom (European Atomic Commission) is 13.5 pCi/g. To date, there is no unanimity on the "safe limit" for radioactive exposure due to PG. As scientists come up with more findings, the safe limit continues to fluctuate. The Environmental Protection Agency (U.S. E.P.A.) and the Surgeons General's Office have urged widespread testing for radon. They estimated that as many as 20,000 lung cancer deaths are caused each year by radon. Next to smoking, radon is the second leading cause of lung cancer. According to a US News & World Report the EPA is currently "weighing whether to classify the gypsum stacks as hazardous waste under federal statutes, a move that would force the industry to provide strict safeguards" (to nearly 1 billion tons of waste). PG has been used extensively in cement, wallboard, and other building materials in Europe, Japan, and Australia. In at least some cases, this has been because of the absence of low-cost natural gypsum and/or scarcity of long-term storage space. In the United States use has been very limited in the past and there is not any current use. Largely because of the naturally occurring radioactivity associated with this material, the U.S. Environmental Protection (EPA) rules prohibit any disposition other than indefinite storage except under a special permit. By special permit is meant for limited agricultural use and research purposes. In India, PG is used to make construction materials such as gypsum plaster, gypsum ceiling tiles, boards, panels and marbles/blocks. It is promoted extensively by the Building Materials and Technology Promotion Council (BMPTC), ministry of urban development. Based on BMPTC's recommendation, the government has even exempted PG from excise duty. Hence, in addition to what is produced in the country, PG is also imported from countries such as Jordan and Morocco. In Australia, by comparison, the current radiation limit on PG construction materials has been set at one tenth of the international limit. Gypsum is one of the primary chemicals used in the manufacture of cement. Cement, or Portland cement, is defined as "a hydraulic cement, obtained by burning a mixture of lime and clay to form a clinker, then pulverizing the clinker into powder. The greenish gray powder is composed primarily of calcium silicates, calcium aluminates, and calcium ferrites. When mixed with water (Hydrated), it solidifies to an artificial rock, similar to Portland stone." A Portland Stone is a yellow limestone from the Isle of Portland, in Great Britain. The chemical composition of Gypsum is CaSO4-2(H2O) which is called Hydrated Calcium Sulfate. Cement is used in the production of concrete. PG is radioactive Calcium Sulfate. It can be used to make cement. The cement, in turn, can be used to make concrete wall panels for the construction industry. 99% of the radiation (Radon Gas) associated with PG cannot scientifically escape the concrete wall panel thereby becoming the permanent tomb (fate) of all of the radiation byproducts of PG. If the Phosphogypsum Stacks were managed either as a hazardous waste or as an ordinary municipal solid waste, i.e., delivered to a concrete wall panel manufacturing facility for a tipping fee, the radioactive wastes could be made to entirely disappear over time. One concrete wall panel company with visions of value in Phosphogypsum Stacks is now proposing this permanent solution. The company plans on using waste coal piles as one of the concrete additives. Another bit of gold from a pile of waste phosphogypsum one might conclude. Tar Sands refer to worldwide crude bitumen (bitumen) deposits that occur in more than 70 countries. For marketing reasons, those engaged in bitumen mining activities have changed the somewhat dirty "tar sands" designation to wealthy sounding "Oil Sands". The largest bitumen deposits are in Canada followed by Venezuela. Bitumen is processed into synthetic crude oils. The synthetic crude oils, in turn, are pipeline transferred to refineries where they are processed into gasoline, diesel fuel, jet fuel, natural gas liquids, and other refined products of commercial value in the same manner as naturally occurring crude oils are refined. Municipalities, pulp & paper mills, sugarcane factories, coal mining, and phosphate fertilizer production are well known to produce significant waste volumes. The waste volumes generated by oil sands bitumen production likely exceed the combined wastes of municipalities, pulp & paper mills, sugarcane factories, coal mining, and phosphate fertilizer production by a factor of 10 to place a perspective on the volume of massive oil sands wastes. Oil Sands Strip or Surface Mining Operation Overburden Waste Pile Sits Atop An Oil Sands Open Pit Surface Mine Canadian oil sands can be mined using both surface (strip mining) and below surface (in situ) technologies. About 80% of Canadian oil sands are too deep for surface mining and therefore the bitumen must be extracted in situ. In every other country 100% of the oil sands are too deep for surface mining. The bitumen extraction process uses hot water flotation to remove a thin coating of oil from grains of sand. Naphtha is then added to thin the bitumen so that it can be pumped. About two tons of oil sand must be mined in order to yield one barrel of oil. The Canadian oil sands have a bitumen content of 10-12%. For each barrel of oil recovered, 2.5 barrels of liquid waste are pumped into huge tailings ponds. The liquid wastes consist of sand, silt, clay, and unrecovered oil. In these ponds, the sand, silt, and fine clays slowly settle to the bottom. Then as much water as possible is pumped back to the extraction plant and reused in the extraction process. Because of the bitumen that remains in the tailings, the ponds pose a number of environmental risks including the migration of pollutants into the groundwater system and leakage into the surrounding soil and surface waters. Approximately six cubic meters of tailings are created for every cubic meter of bitumen produced. The tailings are comprised of 3-5 cubic meters of water and approximately 1.5 cubic meters of fluid fine tailings. Fluid fine tailings can take anywhere from a few decades to 150 years to settle out.

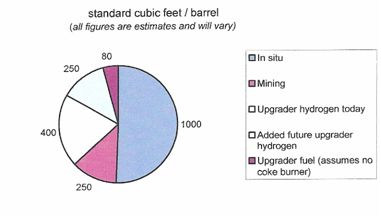

Typical Oil Sands Tailings Ponds Producing the final synthetic crude oil from bitumen requires two stages of upgrading. The first stage cracks the large bitumen hydrocarbons into smaller molecules. This is done using either coking or hydrocracking, or both. In the coking process, excess carbon is removed when high temperatures (around 500ºC) crack the bitumen molecules by vaporizing them. The excess carbon forms a solid residue called coke. The coke, which resembles coal, is then stockpiled as a waste by-product. Hydrocracking involves the addition of hydrogen to bitumen molecules that are cracked using a catalyst, such as platinum. The second stage of upgrading is called hydrotreating whereby high pressure and temperatures (300-400ºC) are used to remove nitrogen and sulphur. In hydrotreating, metals, sulphur, and nitrogen are removed using a catalyst in a hydrogen environment. The nitrogen is removed as ammonia and is usually used as a source of fuel, while the sulphur by-product is converted to elemental sulphur and either transported for use in other industrial processes (e.g., production of fertilizers) or stored in massive sulphur blocks. Natural gas is used both to generate the heat necessary to extract the bitumen from the oil sands and as a source of hydrogen to upgrade the bitumen into synthetic crude oil. For surface mining and upgrading, about 250 cubic feet of natural gas are used for extracting and another 500 for upgrading. For in situ production, about 1000 cubic feet are used for extracting and another 500 for upgrading. These natural gas costs amount to 15% and 60% respectively of the total operating costs of surface and in situ mining operations. The energy intensive production methods translate into the requirement to use the energy equivalent of one barrel of oil to produce three barrels of synthetic crude. Production of conventional oil requires much less energy. Bitumen production continues around-the-clock. Trucks take the tar sand to crushers, where it is broken down into cantaloupe-size chunks. From the crushers, warm water is added to the sands which are piped to rotating drums where the sands and water are mixed further to reduce the chunks to golf-ball size. At the end of 2003, 32 companies representing 59 projects were operating in the Canadian oil sands according to the Alberta Department of Energy. Combined, these companies produced 938,000 barrels per day of bitumen with production on the increase. The production companies are emoting their confidence in continuing marketplace success. According to Suncor's Rick George, "A large part of the rest of this industry is chasing the world for reserves…We have reserves…We have no exploration risk and also have no decline curve, so we have a completely different business model from the conventional crude oil producer" (Moritis, Guntis, Suncor's George: "Oil Sands a long-life, low-risk resource", OGJ 102.11, March 15, 2004, pp. 37-38.) The massive bitumen black gold rush appears unstoppable. Such is not the case, however, as all that glitters (glisters) is not gold. Immense problems on the immediate horizon consist of:

Not to worry as a total scientific solution is now being proposed. Naphthenic acids are natural constituents of petroleum, where they evolve through the oxidation of naphthenes (cycloalkanes). This diverse group of saturated mono and polycyclic carboxylic acids can account for as much as 4% of raw petroleum by weight (Brient et al., 1995), and represents an important component of the waste generated during petroleum processing in some situations. For example, in the Athabasca oil sands industry near Fort McMurray, Alberta, Canada, naphthenic acids become dissolved and concentrated in tailings water as a result of the hot-water process used to extract bitumen from mined oil sands. These tailings are then amassed in large holding

Oil Sands Natural Gas

Demand ponds in the immediate area. The Athabasca oil sands (AOS) deposit covers about 42,000 km2 surrounding Fort McMurray (57° 3.07` N, 111° 36.02` W), approximately 440 km northeast of Edmonton, Alberta. It is the largest of 4 major oil sands deposits in the province and contains over 200 billion cubic meters of petroleum, making it the world's largest single oil deposit (AOSTRA, 1990). Oil sands are a mixture of bitumen (crude petroleum), sand, and water. Separation of bitumen from other components is accomplished by the Clarke Hot Water Extraction process, where mined oil sands are mixed with hot (79-93°C) water and caustic soda (sodium hydroxide). After the bitumen is removed, residual sand, clay, and water, along with other inorganic and organic contaminants, are diverted to settling ponds. By 2025, an estimated 1 billion m3 of tailings pond water (TPW) will have accumulated as a result of mining the AOS (Herman et al., 1994). A consequence of the hot water extraction process is that the alkalinity (pH = 8) promotes solubilization of naphthenic acids thereby concentrating them as mixtures of sodium salts in aqueous tailings. The actual amounts of naphthenic acids in the holding ponds of the two major companies operating in the AOS, Syncrude Canada Ltd. (Syncrude) and Suncor Energy Inc. (Suncor), are typically between 80 and 110 mg/l (FTFC, 1995). The bioavailability and persistence of naphthenic acids in contaminated waters are believed to be high. These compounds are highly soluble and have an extremely low volatility (Henry's constant = 8.56 x 10-6 atm x m3/mol). Sorption to dissolved and particulate organic matter is limited by the polarity of dissolved naphthenates. Large amounts of process-affected water are generated from the extraction of bitumen from the oil sands in Alberta. The tailings are placed into settling basins prior to reclamation and consist of sand, clay, unrecovered bitumen, naphthenic acids (NAs) and polycyclic aromatic hydrocarbons (PAHs). All of the organic constituents can be anaerobically digested to produce methane gas. Methane gas is a near equivalent to natural gas. In addition to the tailings, other area wastes consist of municipal solid wastes (MSW), sewage, cooling water, dyke (dike) seepage, site drainage, muskeg, overburden, mine runoff, and mine depressurization water, coke, and sulfur. A fine slurry mixture of the solid wastes with the liquid wastes can be anaerobically digested to produce methane gas. The liquid effluent from the digester can be separated into liquid fertilizer concentrate and reverse osmosis (RO) water. The saline free RO water can be used for high quality extraction water and steam production with excess going to the river. The methane gas can be used to augment or even replace the dwindling supplies of natural gas. Since the digester solids (digestate) still contain valuable minerals they can be processed to yield their Titanium and Zirconium minerals for sure, and possibly Tourmaline and Pyrite as well. After mineral recovery, the digestate will still contain clays. The clay constituent of the digestate as well as coke and sulfur wastes may be added to Alberta area phosphogypsum stacks from the phosphate fertilizer industry to produce cement.

Typical Alberta Phosphogypsum Stacks The non-clay constituents of the digestate may be used to produce concrete wall panels for the building industry. The concrete wall panels may be used in the construction of a large building to house the anaerobic digester, a photobioreactor to grow microalgae, process equipment to produce biodiesel from microalgae, and all associated processing operations. But wait, there's more. The biodiesel will be further refined through distillation to produce SuperBiodieselTM and BioLubricantsTM. The SuperBiodieselTM can likely be used for modern jet fuel as well as all other diesel powered transportation and equipment without regard for cold weather limitations. The biodiesel based biolubricants can possibly be used as a direct replacement for high quality synthetic lubricants. The superbiodiesel can be used at the project site to replace petroleum diesel with excess to the marketplace. The superbiodiesel can also be used to replace the dwindling supply of condensates for bitumen dilution. The ammonia produced during hydrotreating can be used to generate electricity by adding it to the methane fuel. The associated combustion reactions are: CH4 + 2O2 → CO2 + 2H2O + 890 kJ 4NH3 + 5O2 → 4NO + 6H2O + 905 kJ All oxides of nitrogen formed during combustion are beneficially used by the microalgae within the enclosed photobioreactor. The proportion of ammonia gas added to methane gas can vary from 0 - 100% without adverse impact on power generation because the associated heats of combustion of the two gasses are quite similar. The inexpensive methane gas produced can be used at the project site for extraction, upgrading, and to power generation equipment. The inexpensive methane gas may also be used to revitalize the local phosphate and urea fertilizer industries. At the end of the day phosphogypsum stacks, tailings ponds, methane gas emissions, carbon dioxide gas emissions, MSW piles, coke piles, sulfur piles, and overburden waste piles begin to disappear while additional energy supplies are being produced. The inexpensive anaerobic digestion produced methane would likely enable the full realization of in-situ oil sands making the entire Canadian crude bitumen production fully sustainable over the life of the entire bitumen deposits. As the microalgae photobioreactor continues to grow in size and capacity the production of SuperBiodieselTM will gradually replace the production of bitumen thus making the energy production facility permanently sustainable. The proposed total solution for site redevelopment fully complies with all Kyoto Protocols thus tending to reverse global warming. The following diagram shows the proposed total solution. Yet another bit of gold from piles of oil sands wastes one might conclude.

Thirty Five years in design, marketing, new product development, plant operation, and general management of water purification equipment manufacturing and supply. |

|

The content & opinions in this article are the author’s and do not necessarily represent the views of AltEnergyMag

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

C.G.

(Chuck) Steiner, BS, JD

C.G.

(Chuck) Steiner, BS, JD