In total, the site connected 5 systems to 5 meters in order to generate over 85% of the net energy needed by the course.

Case Study - Windward Nazarene Bay View Golf Course

Contributed by | SolarEdge

In 2012, the Bay View golf course decided to start producing its own energy through solar. On five separate facilities with five separate metering systems, they accomplished this task generating around 85% of their total energy through a SolarEdge enabled, optimized PV system.

Choosing the Right Technology

Choosing the Right Technology

HEC designers evaluated both central inverters and module level electronics for the installation. They initially decided

upon micro inverters due to the multi-faceted design of the installation, moderate shade concerns and difficulty in

utilizing all of the rooftop area. However, they soon learned about a new technology that might be able to help them

improve the design and strengthen the economics of the project even further.

Optimized with SolarEdge

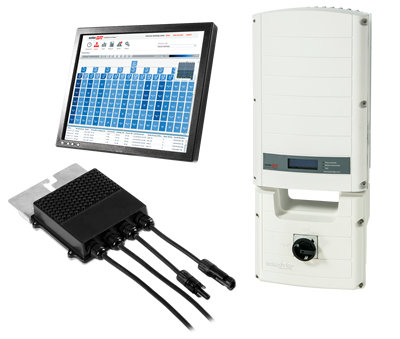

HEC Designers assessed the newly launched SolarEdge commercial SE20k inverters and discovered that they could

accomplish a similar design to micro inverters but at a lower cost and with increased energy production. “SolarEdge SE20k inverters provide native 480Vac support, and do not require transformers that come with additional

cost and additional power losses,” said Josh Mason,

Commercial Solutions Representative.

Furthermore, the economics of SolarEdge on a large project were better due to Balance of Systems savings and a lower head to head charge for the inverters.

Maximum Rooftop Utilization

HEC were able to use more than 90% of the South East and South West facing rooftop surface to deliver an unparalleled solution to the customer.

The final design included 5 systems:

- 25 kW for lighting

- 21 kW to charge golf carts

- 86 kW for powering the kitchen

- 21 kW for powering the driving range lights

- 24 kW for powering the pro shop and mini putt

In total, the site connected 5 systems to 5 meters in order to generate over 85% of the net energy needed by the course.

The content & opinions in this article are the author’s and do not necessarily represent the views of AltEnergyMag

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product