The new system including 100 kW generator is mobile and needs less construction material than wind turbines. Additionally the Kitepower system can flexibly use winds up to an altitude of 500 m.

Clean Energy from High Above

Contributed by | maxon motor

Reprinted with permission from the maxon motor drive.tech blog:

Globally the number of wind turbines producing sustainable energy keeps growing. But there is also another, newer method to make use of wind energy. A Dutch team is currently changing an entire industry.

Johannes loves kites. The passionate kitesurfer also sails the skies in his work, and has big plans: As co-founder and CEO of the startup Kitepower, he wants to turn the wind energy sector upside down – by producing electrical energy with kites.

The principle seems simple: The system for generating power consists of a generator on the ground that is connected directly to a cable winch. The kite keeps pulling the cable upward by flying a figure eight repeatedly and thus creating a strong tractive force. This continues up to a height of 500 m. Thereafter, the cable is retracted – a step that requires only little energy – and the entire procedure is repeated.

Cooperation with the TU Delft

The idea is not new. The Delft University of Technology (TU Delft) in the Netherlands set up a team to research kite energy as early as 2004. The concept kept developing over the years and the group grew. But it took until 2016 for the startup Kitepower to be born from it. The company continues to have close relations with the TU Delft. In addition to the core team of ten people, there are always several students working on the project. “That helps us to tackle problems with an open mind and means we are always getting new viewpoints,” says Johannes Peschel.

More green energy

The long history behind Kitepower helped the company to make a lot of progress in a short time. This summer, the team started up the first prototypes and tested them thoroughly. The first commercial version is scheduled for the end of 2018. It is an attractive alternative to diesel generators and even to wind turbines. The new system including 100 kW generator is mobile and needs less construction material than wind turbines. Additionally the Kitepower system can flexibly use winds up to an altitude of 500 m. According to the developers, this makes the system twice as efficient as existing technologies.

Johannes Peschel wants to use his product to contribute to a better world: “The world population is now finally taking climate change seriously. And our solution aims at generating more green energy, by replacing coal and diesel generators. For example on islands, in secluded communities or in military camps.”

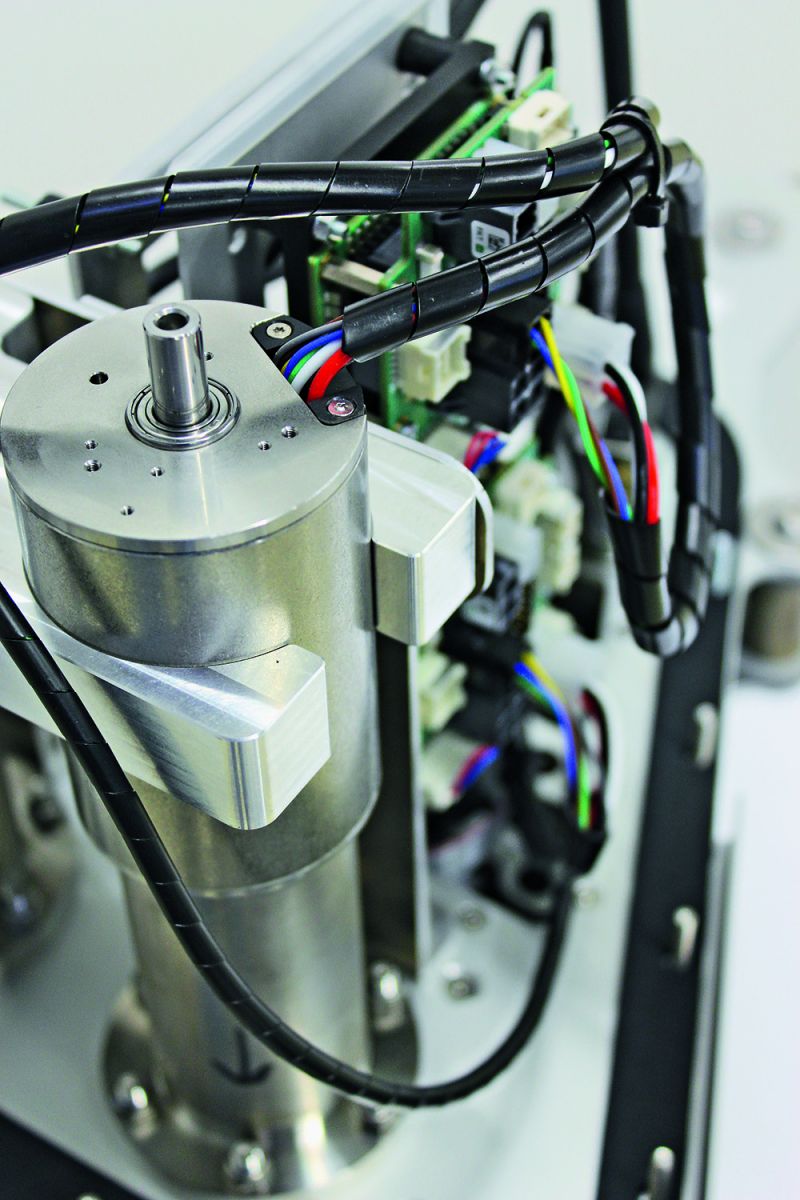

The steering system was developed by maxon motor in Germany and has been equipped with several drive components.

maxon brushless DC motor: EC-i 52, 180 W.

Both sides profit from each other Kitepower is developing its system in cooperation with several industrial companies, among them maxon motor. The company is co-developer and supplier of the important control unit for the steered kite, once more proving its skill as system specialist. The unit, which consists of 1000 unique parts, requires perfect interaction between the motor, gearhead and electronics. According to Dominik Frey, the responsible project manager at maxon’s Sexau location (Germany), it was quite a challenge to integrate the different sensors, transmitters, receivers and batteries. Additionally extreme radial forces act on the gearhead. Therefore the bearings of the drives were reinforced. The products used include the new brushless EC-i 52 in combination with the GP 42 UP planetary gearhead and an encoder. The motor is frequently used in robotics, as it has a high torque and compact design.

Kitepower CEO Johannes Peschel says: “We are happy that maxon was able to fulfill all our requirements.” And he is positive about the future of the cooperation. “maxon as a global player and our company as agile startup can significantly profit from each other.”

The content & opinions in this article are the author’s and do not necessarily represent the views of AltEnergyMag

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product