California startup HahaSmart aims to become low-cost disruptor in solar

Metal Roofing Makes Solar a More Cost-Effective Residential Option

A Guide to Safely Installing Solar Panel Arrays to Any Property Type

DuPont Microcircuit Materials Introduces New Solamet PV76x Photovoltaic Metallization Pastes

Optimizing Solar Plant Implementation

One With The Roof

Solar Energy Moves into a Brighter Future

Rail-less Residential PV Mounting

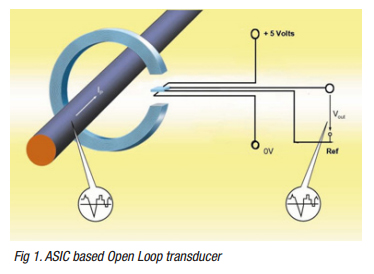

ASIC Based Current Transducers

Using Elastomeric Roof Coatings to Resolve Existing Roof Systems & Solar PV Life Cycle Disparities

A New Class of Rogowski Coil Split-core Current Transducers

Corrosion Control for Wind and Solar Equipment

Balance Of System Innovation "Clicks" for a Competitive Edge

Aluminum Continues KnowledgeSurge in Cost-driven Solar

How to choose and implement current sensors

Records 31 to 45 of 53

First | Previous | Next | Last

Featured Product

.jpg)