Aerones Secures $62M in Oversubscribed Financing Round

Funding will be used to expand globally, boost R&D in AI and robotics, scale manufacturing, and enhance predictive maintenance for the wind industry.

Boosting Wind and Solar Power Sustainability with Corrosion Prevention

With corrosion as a key enemy of wind and solar longevity, Cortec® reminds manufacturers not only of the importance of proper materials selection during the design phase, but also of the benefits of a few simple corrosion preventative steps during shipping and maintenance.

Monitoring Tools for Manufacturing Plant Maintenance

Electrical power delivery systems are usually the most impactful on plant operation. The cost of failure of certain pieces of equipment can quickly escalate into multi-millions of dollars of equipment replacement costs and production downtime.

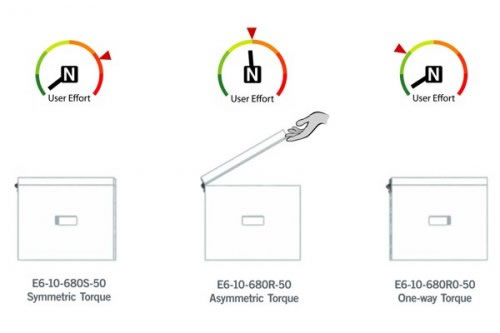

Southco: What is a Friction/Torque Hinge?

A torque hinge uses friction to control the movement of a door, lid, or other type of panel. It allows the panel to be held in any position along its range of motion, without additional hardware or support.

Polymeric Leading Edge Protection Extends Lifespan of 42 Wind Turbine Blades

The use of this technology is based on a circular economic business model: repairing damaged assets rather than replacing them. Not only does this mitigate the carbon footprint, but it is also enables the asset owner to make significant financial savings as well.

World's first in-situ major component exchange on floating wind turbine successfully completed

Applying this groundbreaking new process has eliminated the need for tow-to-port operations, which has previously been the only way to perform MCEs at floating offshore wind farms.

Turbine Blade Inspection Using Vibro-Thermography

This article explores the application of vibro-thermography as an effective non-destructive testing (NDT) technique for detecting both surface and subsurface cracks in turbine blades.

Study: Robots and AI Offer Significant Carbon Emissions Reductions by Operating Centuries Old Industries Better

By incorporating better use of data into some of the world's most carbon-dependent industries, the study found the equivalent of up to 18% of U.S. emissions could be eliminated by better operation.

ABB survey reveals unplanned downtime costs $103,000 per hour

It emphasizes the importance of effective maintenance strategies and service partnerships. 92% of respondents are interested in how outcome-based maintenance agreements can boost business success

What Role Does Polymeric Technology Play in Burgeoning Wind Industry?

Designed to safeguard the integrity of wind turbine blade leading edges for the long term, polymeric repair and protection technology plays a critical role in supporting this burgeoning industry.

Solar/Wireless Site Cameras Monitor Substations and Renewable Power Plants

CIPCO turned to Sensera Systems for a flexible camera solution that would meet the site security needs of the solar power plant project and the substation.

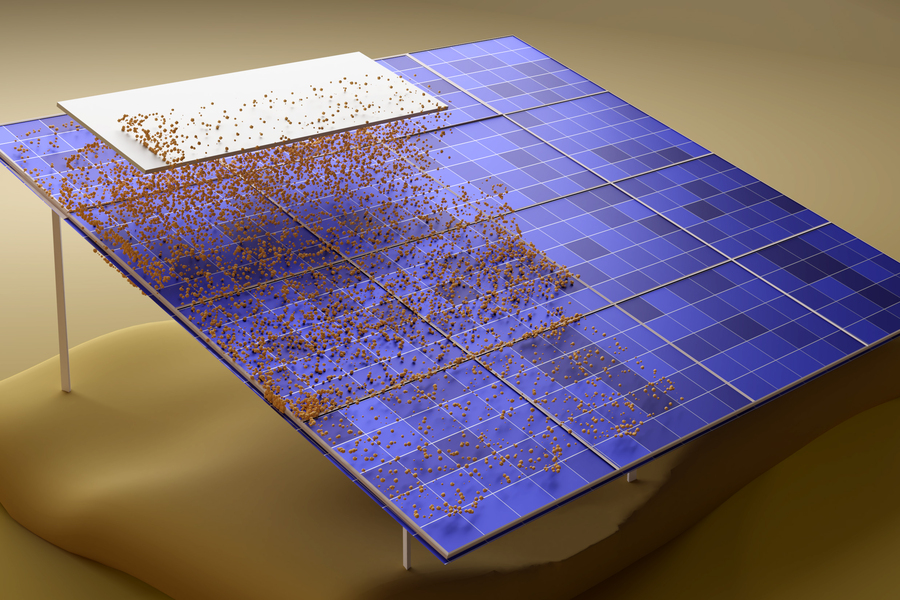

How to clean solar panels without water

A new cleaning method could remove dust on solar installations in water-limited regions, improving overall efficiency.

Solar Panel Cleaning and the Importance of Preventative Maintenance

There are several challenges, mainly due to the area where the cleaning is needed. For example, in Saudi Arabia, there are a lot of sandstorms. Therefore, the panels need to be dry cleaned almost every day.

Understanding Wind Turbine Fire Protection

A whopping 90% or more of wind turbine fires originate in the nacelle. The nacelle contains the gear box, the generator, the controller, the low- and high-speed shafts, and the brake-and it (the nacelle) sits atop the tower.

Preventative Maintenance for Renewable Energy

Engineers and scientists developed renewable energy systems to reduce society's adverse environmental impacts. We can align clean power devices with the systematic purpose by extending their life span and increasing their production.

Records 1 to 15 of 42

Featured Product

Terrasmart - Reduce Risk and Accelerate Solar Installations

We push the limits in renewable energy, focusing on innovation to drive progress. Pioneering new solutions and ground-breaking technology, and smarter ways of working to make progress for our clients and the industry.