Future Proofing Off-Grid Systems Against Obsolescence

The ReadyEdge is a system monitoring and site management device that connects to one or multiple compatible Morningstar charge controllers to aggregate their operating data and enable remote management.

Making the Case for Cable Ties in Solar

I can hook you up with a cable tie that'll perform for 40 years or more in harsh conditions. Or maybe it will only last half that long, or much less. Your call. Install it wrong, and its potential longevity is meaningless.

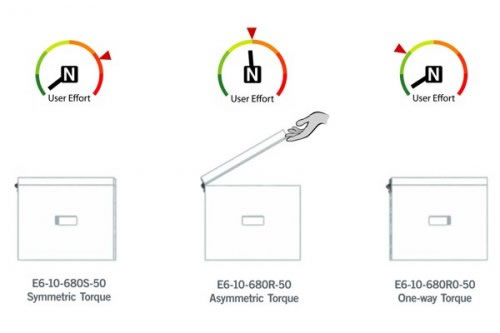

Southco: What is a Friction/Torque Hinge?

A torque hinge uses friction to control the movement of a door, lid, or other type of panel. It allows the panel to be held in any position along its range of motion, without additional hardware or support.

Against great odds: Solar power in the Antarctic

Temperatures below -89 °C, winds over 200 km/h, extreme variances in hours of sunlight, with up to 16 hours in the summer and only two during winter, pose tremendous challenges for both research teams and equipment.

Ensuring Solar Connector Safety & Performance Through High Quality Equipment & Proper Installation

There are countless decisions one needs to make when installing a new solar power system, many of which revolve around crucial cost and quality outcomes. The end user wants to save money where they can, but also wants to be sure they're getting the highest quality.

When High Temperature Meets Photovoltaic Systems

Through rigorous testing and verification with actual application data, Beny Microinverter BYM2800W performs exceptionally well in hot weather conditions. Even under an ambient temperature of 50 degrees Celsius, it can maintain 100% output power.

Six Common Questions About Power Supplies - Solved!

In this Allied Expert Advice article, Altech Corporation's Automation Product Manager, Laszlo Gyorgypal, answers six common questions about power supplies to help you select the best solution for your industrial automation application.

A Deep Dive Into Improving The ROI For Commercial PV Solar Systems

As with any investment, the two main ways to improve the ROI of a commercial PV system is to increase energy production (and therefore annual revenue) and decrease lifetime costs. Let's take a deeper look at how this can be done in commercial PV installations.

How Keeping It Simple Can Lower O&M Costs

To mitigate the increasing cost of running a utility-scale solar project, many owners and operators have switched their focus from CapEx to operations and maintenance (O&M).

Making Solar an Even Safer Investment

As more businesses, utilities, and state bodies look to solar energy to help them meet their carbon reduction goals and cut energy costs, safety is coming under ever more scrutiny.

Avoid Cross-mating of PV Connectors

Not only the selection of quality components but also their correct handling is crucial for the PV plant's profitability and safety. Therefore, it is essential to know and understand the technical impacts when installing and connecting the various elements.

The First PV Connectors for Harsh Environmental Conditions

Requirements for operating electrical installations in ambient temperatures over 70°C or at altitudes higher than 6,500 feet differ from the requirements for standard installations due to the different climate conditions.

Correct Use of Aluminum Core Cables in PV Systems

In PV systems, it is recommended to use copper core AC cables. If you need to use aluminum wires, pay attention to the transition method when connecting aluminum cables to copper wires or equipment with copper terminals.

The Top 10 Most Common Myths about Traditional DC Power Optimizers: Part 1

In this series, we'll debunk common misconceptions and shed some light on how performance is impacted by MLPE technologies.

How Silicon Carbide is Changing Solar Power Systems

Silicon carbide enables solar inverters to be lighter, smaller and more efficient. Using silicon carbide power components instead of silicon for solar inverters can save 10 megawatts for each gigawatt and 500 watts/sec in operations, representing significant energy savings.

Records 1 to 15 of 23

Featured Product

U.S. BATTERY RENEWABLE ENERGY SERIES DEEP CYCLE BATTERIES

Our RE Series batteries are designed to provide the highest peak capacity, longest cycle life, and greatest reliability for use in industrial or residential renewable energy applications. Renewable Energy Series batteries utilize the company's exclusive XC2™ formulation and Diamond Plate Technology® to create the industry's most efficient battery plates, delivering greater watt-hours per liter and watt-hours per kilogram than any other flooded lead-acid battery in the market. Our Deep Cycle batteries are engineered to work with solar panels as well as other renewable energy applications.